See all the latest news from the Sign, Print, Graphics & Display Industries or simply browse any category from our menu. From Amazing Projects to Wide Format Digital Printing, Visual Impact Magazine has all the latest news and emerging technologies. To find out more join our newsletter and have all the latest news direct to your email.

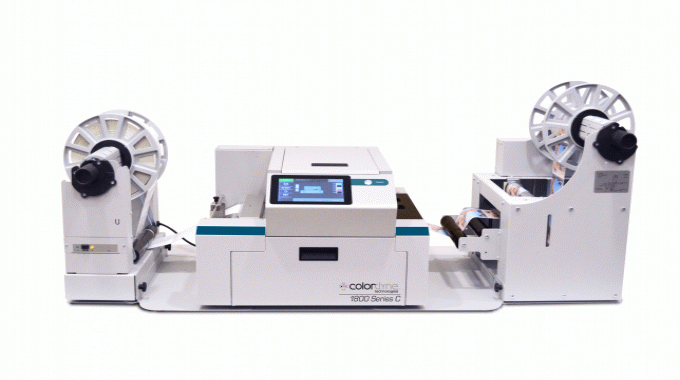

Colordyne Technologies, a manufacturer of full colour digital inkjet label and tag printers, has released an enhanced entry-level label printer, the 1800 Series C. The addition to Colordyne's suite...

February 06 2019

Colordyne Technologies, a manufacturer of full colour digital inkjet label and tag printers, has released an enhanced entry-level label printer, the 1800 Series C. The addition to Colordyne's suite of products provides brand owners and private label manufacturers with affordable and versatile in-house label and tag printing capabilities.

The 1800 Series C is a continuous printer for on-demand short run label and tag production. The press features a flat, unobstructed printing path and redesigned printhead maintenance station. These press enhancements eliminate the need to break the web to clean the printhead during runs, increasing run lengths and improving print quality.

"Colordyne's newest system provides additional features that customers have been looking for in our entry-level benchtop solutions," says Taylor Buckthorpe, director of sales at Colordyne Technologies. "This includes an on-press job library that allows brands to better manage their label inventory on-demand, eliminating the need to manage a stock of pre-printed labels and reducing waste from unused label inventory."

The job library can be accessed through the 1800 Series C's on-press touch screen user interface. The touch screen improves the user experience by providing quicker access to frequently used printer functions, such as: printhead maintenance, job setup, media settings and more. Additionally, the user interface was designed to be easy to use, so operators of any skill level can run and maintain the printer.

"Companies are looking for a solution to affordably print smaller label quantities in a just-in-time business model," says Buckthorpe. "The 1800 Series C gives brand owners and private label manufacturers the opportunity to bring high-quality label printing in-house. These companies are increasing their productivity, expanding marketing capabilities and improving customer satisfaction."

The 1800 Series C can run in multiple modes, including: print-to-cut, fanfold and roll-to-roll, when used with optional unwind and rewind attachments. The 1800 Series C prints in full colour (CMYKK) using a single Memjet water-based dye printhead and ink set. The press can print at a premium resolution of 1600 x 1600 dpi and run at speeds up to 60 fpm.

Vale – Jeff Gittus 1959 – 2019 The Active family, and much of the Australian print and manufacturing industry is mourning the loss of Jeff Gittus, founder of Active Display...

February 06 2019

Vale – Jeff Gittus 1959 – 2019

The Active family, and much of the Australian print and manufacturing industry is mourning the loss of Jeff Gittus, founder of Active Display Group.

Jeff passed away peacefully on Friday after undergoing his second lung transplant a little over 2 weeks earlier.

Jeff founded Active Sites Alive in 1985 after establishing his own signage business from home only 5 years earlier.

Through Jeff’s vision, personality and nature, Active has provided employment for thousands of people for over 30 years.

It’s an extremely sad time for the people at Active, their clients and the retail marketing industry at large.

Jeff was part of many industry organisations, including a pioneering founder of POPAI (now Shop!) in Australia.

Jeff considered everyone at Active to be his family, and family was at the heart of what he valued most.

On behalf of all the industry, we pass on our condolences to Jeff's family and the team at Active.

Epson has again been recognised this year as one of the 2018-19 Derwent Top 100 Global Innovators. They are also amongst the best of the best being one of only 35 organisations to have been recogni...

February 05 2019

Epson has again been recognised this year as one of the 2018-19 Derwent Top 100 Global Innovators. They are also amongst the best of the best being one of only 35 organisations to have been recognised for the eighth year in a row since the inception of the program in 2011. These innovators exhibit consistently strong performance in successfully obtaining rights to their innovation, seeking wide protection and global markets for potential products and services based on that innovation and are recognised by their peers as creating leading innovation for others to build on.

Clarivate Analytics cited reasons for Epson’s inclusion in the top innovators list including the fact that Epson regularly files high volumes of patent applications and had good success this year in converting these to granted patent rights.

They also showed improved performance in global filing of inventions filing more within the Quadrilateral authorities (US, Japan, China and Europe) than last year.

Epson holds many patents globally and is working with patent agencies in 20 countries or more at any given time.

“It is an honour to be selected as one of the Top 100 Global Innovators for the eighth consecutive year,” said Toshiya Takahata, executive officer and general administrative manager at Epson. As stated in its Management Philosophy, Epson seeks to become an indispensable company, an ambition that Epson considers to be consistent with the realisation of the sustainable development goals (SDGs) of the United Nations. We will continue to conduct our business and pursue intellectual property activities with the aim of creating a sustainable society.”

For more details about Epson's intellectual property activities go to: https://global.epson.com/innovation/intellectual_property/

The Gallus Labelfire E 340 features CMYK plus digital white, and is intended to provide a different entry point to those looking to produce lowest cost, digital, finished labels in a single pass on...

February 05 2019

The Gallus Labelfire E 340 features CMYK plus digital white, and is intended to provide a different entry point to those looking to produce lowest cost, digital, finished labels in a single pass on an industrial platform.

Launched in 2016, the Gallus Labelfire 340 is an 8-colour digital production system combining UV inkjet printing with in-line embellishment and converting. The inkjet system, co-developed with Heidelberg, features state-of-the-art, 1200 dpi inkjet heads from Fujifilm. Gallus Labelfire E 340 features the same 1200 x 1200 dpi image quality, without orange, violet and green inks.

Gallus stated that the new model can be configured based on the current needs of the customer to provide the lowest cost of entry when it comes to getting started with digital hybrid label printing. The whole system is integrated into Heidelberg’s Prinect print media workflow. Those customers who purchase the five-colour Labelfire will have the ability to upgrade to eight colours and add further embellishing options including screen, cold foil, additional flexo, as the need arises or their business grows.

Michael Ring, head of digital solutions at Gallus, said: ‘We have many customers who want to get into digital hybrid printing, but do not need the complete high-end, fully featured configuration that an 8-colour Labelfire provides. This new 5-colour version allows them to get started in the digital arena but still provides the flexibility for expansion in the future while protecting their initial investment.’

Gallus Labelfire E 340 is available worldwide immediately. Deliveries are expected to start in April.

HP Graphics Solutions Business has launched a personalisation framework, The Personalisation Pinwheel, intended to help brands to accelerate business growth and increase consumer engagement. ...

February 05 2019

HP Graphics Solutions Business has launched a personalisation framework, The Personalisation Pinwheel, intended to help brands to accelerate business growth and increase consumer engagement.

Informed by insights from more than 45 million online conversations in four markets across the globe, the framework hones in on what motivates consumers to personalise – from photo books to magazine covers to consumer packaged goods – and how brands can capitalise on those motivations.

An accompanying infographic outlines the value of the personalised gift market as $31 billion USD by 2021, up 55 percent from 2016 according to statistics from Technavio. Some 70 percent of shoppers are said to be willing to pay at least 10 percent more for personalised products. Figures from Deloitte identify more than 50 percent of Millenials and Gen Z expressing a desire for personalised products.

Nancy Janes, global head of brand innovation at HP, explained: ‘Personalisation is a powerful tool to create meaningful experiences with consumers. It increases brand loyalty and engagement and at the same time accelerates business growth and speed to market. HP’s digital printing capabilities are transforming how consumers connect to brands through personalised packaging and products.’

Charles Ohiaeri, chief fulfilment officer at Zazzle, added: ‘In our eyes, personalisation encompasses far more than just customised or stylised products; it’s about how we can intelligently curate and contour the whole experience for those in our community – makers, designers and consumers alike. HP’s digital printing solutions allow us to serve our customers in ways we would not have considered previously.’

The six spokes of The Personalisation Pinwheel cover:

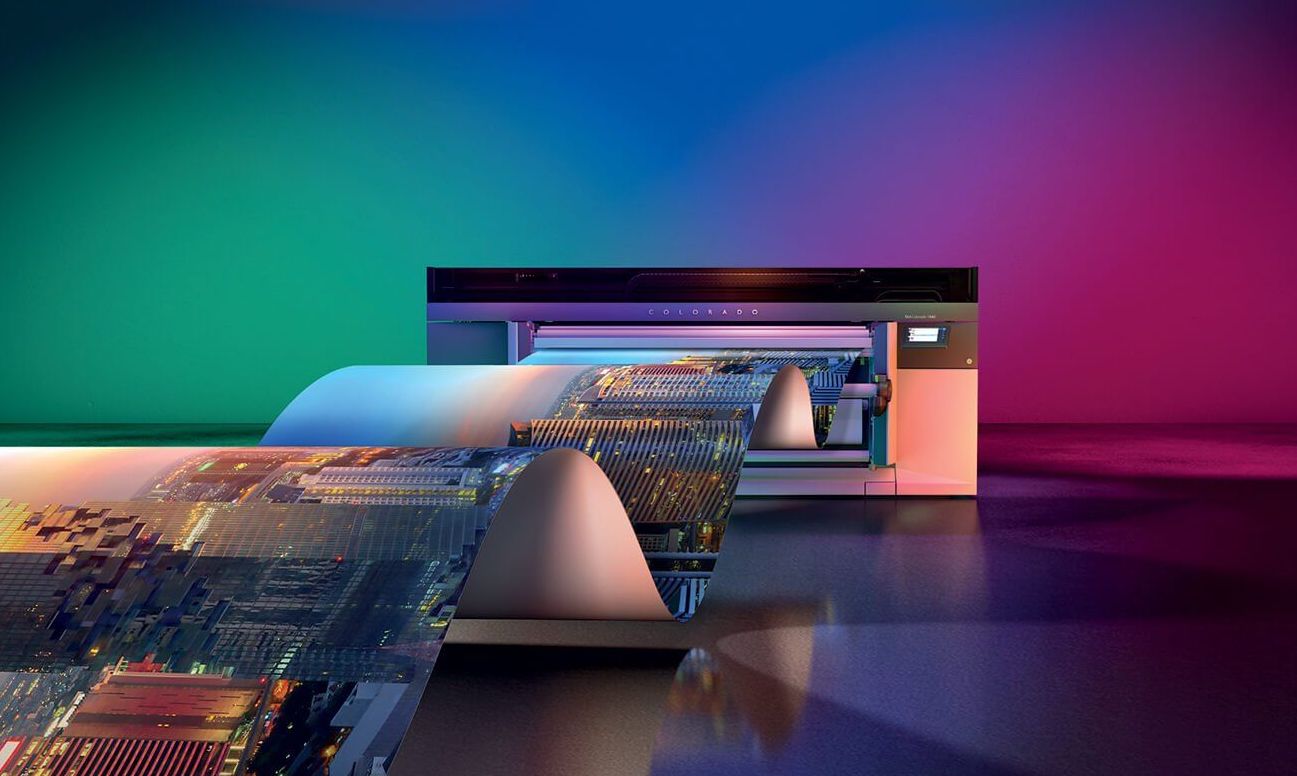

Canon is pleased to announce the launch of the new Océ Arizona 1300 series of high-productivity mid-volume UV true flatbed printers. With its innovations in print speed, ease-of-use and curi...

February 05 2019

Canon is pleased to announce the launch of the new Océ Arizona 1300 series of high-productivity mid-volume UV true flatbed printers. With its innovations in print speed, ease-of-use and curing technology, the Océ Arizona 1300 series is extremely versatile allowing print providers to do more, do it smarter, and do it now.

The latest in the line of Canon's award-winning Océ Arizona printers, the new Océ Arizona 1300 series is a great choice for printers in the sign and graphics industry, for whom print quality and productivity are essential. The Océ Arizona 1300 series has productive print modes, optional light and white ink support, optically clear varnish and enhanced screening to deliver outstanding print quality, print after print. It allows print providers with photographic or fine-art applications to print on a wide range of media, including odd-shaped, heavy, smooth or pre-cut media and unusual objects such as canvas, glass or wood. Customers can choose from three GT models (Océ Arizona 1340 GT, 1360 GT, 1380 GT) with a flatbed print area of 49.2 inches x 98.4 inches, or three larger 121.3 inches x 98.4 inchesXT models (Océ Arizona 1340 XT, 1360 XT, 1380 XT).

The impressive innovations in the new Océ Arizona 1300 series are the extensive application range, integrated Océ Arizona Xpert self-learning technology and instant-on capability. And for the customer who also purchases the Océ Touchstone software, users easily create textured prints, both transparent and opaque, that will even further help expand their applications capabilities and delight their customers.

Imagine … print … learn … repeat

The integrated Océ Arizona Xpert technology allows the printer to learn from what the operator does. This makes it easy and extremely productive to help reproduce complex, multi-layered projects. Just design them once with the intuitive user interface and print them. The printer will learn the recipe for the project, including transparencies and multi-sided printing, which can then be used over and over again.

Ready when you are

With instant-on printing, the Océ Arizona 1300 series printer is ready when the end-user is. The Océ Arizona 1300 series exemplifies speed and productivity, delivering sharp, high-key prints up to 568 square feet per hour and high-density prints up to 380 square feet per hour. The new LED UV curing system offers instant-on capability, allowing operators to start valuable rush jobs without waiting for the printer to warm up.

With the built in Automated Maintenance System (AMS) for hands-free printhead maintenance, nozzle function for all colours can be selectively restored in seconds.

Ready for the future

For customers with an evolving business or application range, the Océ Arizona 1300 series can be upgraded at any time such as by adding additional ink channels up to a maximum of eight, the Roll Media Option, or a Static Suppression Upgrade Kit that provides active suppression of static electricity when printing on hard plastic materials such as acrylic, polycarbonate and styrene. Also, the option to add light cyan and light magenta inks, plus our brightest white ink ever, or optically clear varnish to the ink channels helps enable even higher quality photo and fine-art and high margin applications than before.

Quick, reliable and low-maintenance

The Océ Arizona 1300 series printers are designed for the easy, reliable operation a busy print environment needs. Operators can easily make last-minute adjustments at the printer, such as nesting, batching of complex jobs, step and repeat, mirroring and re-assignment of print modes. Switching between rigid media jobs and roll to roll jobs can be done instantly at the push of a button with no extra tables to deal with. Media handling too is simple and efficient with the built in pin registration system to easily align media on the flatbed table. The new IJC357 UV inks are Greenguard Gold certified, so the prints may be used in sensitive environments such as in schools and hospitals.

https://www.youtube.com/watch?v=teVU22SLvqI&feature=youtu.be

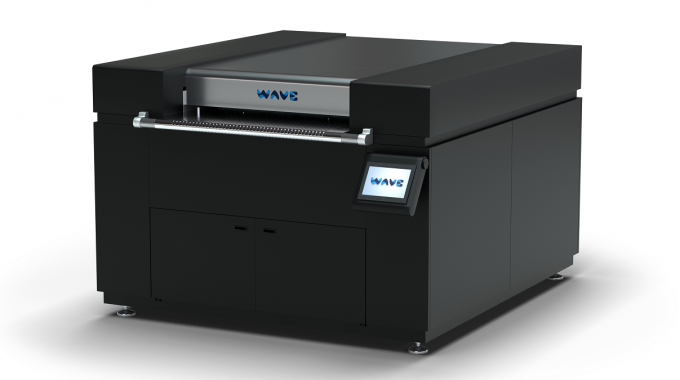

Vianord Engineering has introduced Wave 3P, a new plate processing system for water-based flexographic plates that does not require water replacement. Wave 3P can handle a maximum plat...

February 05 2019

Vianord Engineering has introduced Wave 3P, a new plate processing system for water-based flexographic plates that does not require water replacement.

Wave 3P can handle a maximum plate size of 92 x 120cm (36 x 48in. It can process almost all plate types in the market from 1.14mm up to 2.84mm thickness, both digital and analog.

It has been engineered to enhance the sustainability advantages offered by water washable flexo plates while safeguarding quality washout and superior screenings. As such, an integrated water reclaim system does not require frequent water replacement and only needs to be topped up due to evaporation caused by its working temperature.

Vianord noted that Wave 3P also has a small footprint compared to conventional processing equipment, and fast high-quality washout, perfected by unique LAM residual cleaning and pre-drying features.

Massimiliano Merlo, global marketing and sales director at Vianord Engineering, explained: ‘The innovative Wave product family is answering the flexo industry’s demand of solvent free and fully automated plate making systems.’

Wave 3P will begin to be delivered to the clients from April.

In a move which expands the sales and supply options available to i ts customers in Queensland, Océ Australia has announced t...

January 30 2019

In a move which expands the sales and supply options available to i ts customers in Queensland, Océ Australia has announced the appointment of Charti as an Océ Partner for Brisbane and the Gold Coast.

Charti, large format printing specialists and long-term supplier of printers, media, ink, display systems and supplies, will now be a reseller for Océ’s Technical Document System (TDS) printers in these key Queensland markets, supplying not only the ColorWave and PlotWave series, but also associated toner and consumables.

According to Dale Hawkins, Senior Manager – Indirect & Marketing for Océ Australia, the move will enhance our local supply options for ColorWave and PlotWave customers in these areas, “Charti is a Melbourne-based supplier which offers an extensive range of large format printing equipment, media, ink, display systems and supplies,” Hawkins says. “More importantly for our Queensland customers, the company has support offices throughout Australia which include an extensive warehousing facility in Capalaba, Brisbane.”

Charti will provide the market leading Océ ColorWave and PlotWave series of printers to the Brisbane and Gold Coast markets. While customers are still ‘most welcome’ to order supplies for these printers direct through Océ Australia, which delivers overnight from its extensive warehouse in Sydney, Hawkins says the appointment of Charti means TDS printers in these key Queensland markets have a second source of supply, providing greater convenience, and the option of local supply for even faster turnaround and delivery times.

“Charti has an excellent reputation for both expertise and product quality and we are delighted to partner with them to provide our customers in Queensland with expanded sales and support options,” he says.

“We have a strong and long-standing relationship with the company as a supplier of products from Océ parent company, Canon, and are confident they will be a responsive and reliable business partner for our customers in Queensland, providing the high level of support they need to build their business success.”

Charti’s Managing Director David Cheng has also welcomed the new agreement with Océ with open arms saying, “It’s a perfect strategic fit having two quality brands working side by side to serve our industry.

“The Océ brand and product line-up perfectly complements the Charti offer, making Charti a ‘one stop shop’ for the large format printing industry,” Cheng says. Businesses in Brisbane or the Gold Coast can contact the local Charti team on 07 3914 9900 to start ordering toner and consumables.

www.oce.com.au

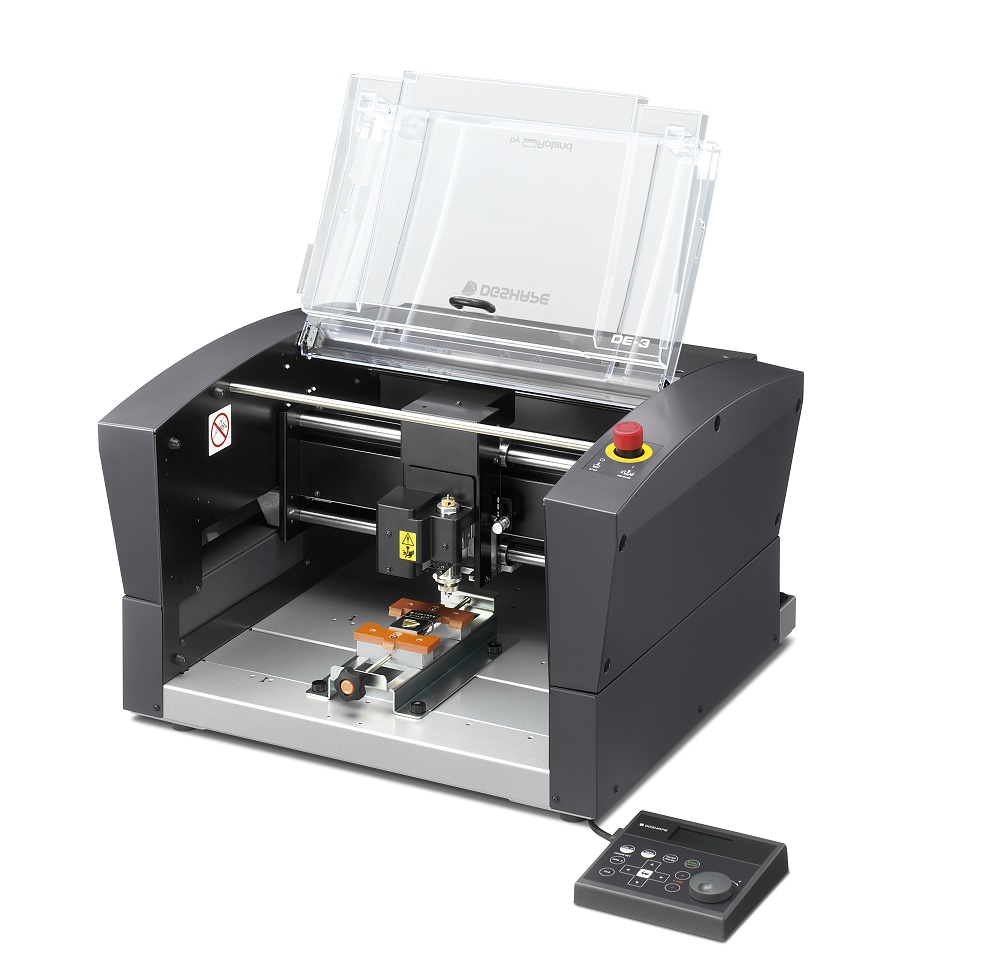

DGSHAPE Corporation, a wholly-owned subsidiary of Roland DG Corporation and a leading provider of digital fabrication tools, including 3D milling machines, 3D printers, and engraving machines, anno...

January 30 2019

DGSHAPE Corporation, a wholly-owned subsidiary of Roland DG Corporation and a leading provider of digital fabrication tools, including 3D milling machines, 3D printers, and engraving machines, announced today the launch of its latest decorating solution, the DE-3. DGSHAPE continues the legacy of Roland engraving with a new model that features laser-pointing technology, ethernet connectivity, automatic depth regulation, and other intelligent enhancements.

According to Hisashi Bito, President of DGSHAPE Corporation, “The DE-3 builds on the legacy of Roland engraving solutions that is advanced today by DGSHAPE Corporation and affirms DGSHAPE’s commitment to providing reliable desktop solutions for the entrepreneur to build their business.”

The DE-3 can produce a variety of engraving applications including industrial nameplates, signage, awards, and gift personalisation. This next generation engraver incorporates many new improvements including: Ethernet connectivity, updated nosecone technology for higher quality engraving on uneven material, data buffer for offline engraving, laser pointer for precise material alignment, and new bundled software: Dr. Engrave Plus. This new software has advanced features such as AI and EPS file support, leveling and drilling functions, and Variable Data Printing.

A cornerstone of all DGSHAPE machines, Bito said, is their ease of use. Operation is as simple as pressing a button. DGSHAPE prides itself on the concept of the “Open System.” This open architecture offers the flexibility of using design software and tooling that engraving professionals are already familiar with. The DE-3 can be connected via USB or LAN which allows for increased flexibility in any environment. Dr. Engraving Plus is a design software that can create new artwork or take existing files from popular design software packages to output to the DE-3 for a true out-of-the-box solution.

The DE-3 easily produces popular engraving applications in a variety of materials. The DE-3 can be installed via USB or Ethernet. An optional centre vice increases the available materials that can be engraved

The ATO is running a series of free workshops and webinars for small businesses that will cover tax essentials, good record-keeping and employer essentials – all to support your business.

January 29 2019

The ATO is running a series of free workshops and webinars for small businesses that will cover tax essentials, good record-keeping and employer essentials – all to support your business.

Small business owners and professionals will learn to free up valuable time to spend on their business and not on their books!

Click on the State links below to view our current offers:

Australian Capital Territory

New South Wales

Northern Territory

Queensland

South Australia

Tasmania

Victoria

Western Australia

You'll benefit by:

• finding out where to go when you need help and more information

• learning how to use the ATO’s online tools and resources to make things easier and free up your valuable time.

For enquiries, email us at sbtalk@ato.gov.au

The labelstock supplier has collaborated with both wineries and converters to develop more than 150 substrates. Avery Dennison has responded to market demand, developing more than 150 ...

January 29 2019

The labelstock supplier has collaborated with both wineries and converters to develop more than 150 substrates.

Avery Dennison has responded to market demand, developing more than 150 constructions specifically engineering for wine and spirits. The company has gone directly to wineries and converters to troubleshoot current customer problems and ideate new ideas.

“The Avery Dennison Wine and Spirits portfolio offers inspiration through classic, premium materials enabling brands to stand out on shelf,” says Vanita Marzette, senior product manager - wine and spirits. “Wine materials cross both wine and spirits, as well as craft beer, because these areas are all following the trend towards premiumisation. We are also seeing more unique/textured facestocks that work across segments. The wine materials offer the added benefit of being able to stand up to ice buckets and condensation.”

To meet demand, Avery Dennison is launching three new collections for its wine portfolio. The Sensorial collection will feature new Ruby Velvet and Black Velvet facestocks. According to Marzette, Avery Dennison’s Sensorial collection adds the senses of touch, sound and even smell to the label. The Sensorial Collection offers label surfaces that feature a soft touch, textured or patterned papers. Some materials offer subtle sounds as fingers move across the surface. Meanwhile, hand-selected trees are used to fashion wooden labels that deliver a delicate, natural scent.

The new Black collection will include Laid Epic Black and Night Skye facestocks. “Black really is the new black, helping a brand to deliver a message of premium, quality content,” says Marzette. “The Black collection is a broad portfolio that reflects dependable quality to deliver outstanding shelf appeal. Materials include structured surfaces, thick to thin facestocks and a choice of different shades. Converters will appreciate the fact that they no longer have to print twice to create a rich, even black label with no white edges and stable hot foiling.”

Finally, the Luminous line, featuring Snowbound White, includes labels that glitter, sparkle and shine to stand out on the shelf.

In addition, Avery Dennison is adding to its sustainability portfolio with Grape Touch, which is made of 15% grape waste sourced from wine production – and Estate Label No. 14, a 100% post-consumer-waste (PCW) paper material that maintains colour and strength, even when wet.

“These products help tell a brand’s sustainability story while delivering performance and shelf appeal that result in sales,” adds Marzette. “Sustainability resonates with many consumers, and that story goes beyond production.”

The wine label goes beyond the facestock, too. Avery Dennison has developed multiple adhesives that are optimised for wine labels–and its customer service team works diligently to pair the right materials and adhesives with a customer’s desired application.

“We offer a range of adhesives that are formulated to work well in ice bucket, heavy condensation environments,” says Marzette. “Our technical resources put our adhesives through a range of testing before they launch, and all of the results can be found in our wine and spirits collateral and data sheets.

“We list all of our service offerings and support programs in our wine and spirits collateral to make it easy for customers to find,” Marzette adds. “Additionally, we have customers service, application consultants and technical leads available to help customers find the right materials for them. We also have our engineered solutions team available to help source and find a material if we don’t have what a customer is looking for.”

Plus, the Avery Dennison Concept lab is comprised of designers that work closely with other designers, converters, brands and agencies in the wine and spirits space to help bring their vision to life.

In the future, Avery Dennison expects to see continued premiumisation and a trend toward more unique facestocks that create pop on the shelf. Marzette adds that brands can create more engagement with their customers by opting for intelligent and interactive labels. Requests will continue for inkjet-optimised materials, too.

And, as is seen in the Luminous collection, a different range of colours will be utilised to further appeal to millennials.

Meet Brett Burns. Ricky Richards Print Media Sales Manager. Brett has been in this industry for over 20 years and hosts a wealth of knowledge when it comes to choosing the right produ...

January 29 2019

Meet Brett Burns. Ricky Richards Print Media Sales Manager.

Brett has been in this industry for over 20 years and hosts a wealth of knowledge when it comes to choosing the right products to use to enhance your designs and printing. He joined the Ricky team last year and has a huge 2019 planned for that division.

If you would like to chat to Brett or the Print Media experts in the Ricky team contact them on 029735 3333 or head over to www.rickyrichards.com.au

Digimarc has introduced a new serialised packaging offering combining Digimarc Barcode and HP Link, which can provide every printed object with a unique identity and offers a cost-effective option ...

January 29 2019

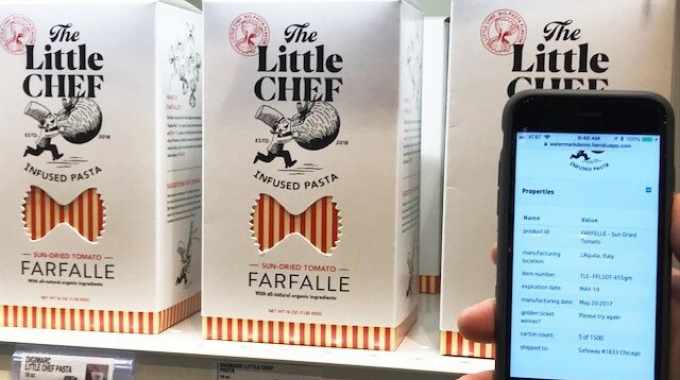

Digimarc has introduced a new serialised packaging offering combining Digimarc Barcode and HP Link, which can provide every printed object with a unique identity and offers a cost-effective option for tackle supply chain problems.

HP and Digimarc offer consumer brands and their digital print providers the ability to apply a serialised global trade item number (SGTIN) on packaging to track and protect a package through the supply chain and at point-of-sale (POS) in retail environments.

It is claimed this new capability will help to combat product counterfeiting and piracy, currently estimated by Frontier Economics and the International Chamber of Commerce to reach $4.2 trillion USD by 2022.

Assigning SGTINs to individual items means that two otherwise identical units of the same product are uniquely identifiable, making it possible to track and trace for brand protection and product origination.

Digimarc Barcode is an advanced visually imperceptible code that can be serialised during printing on HP digital presses of product packaging, retail labels, point-of-purchase (POP) displays and other print output. It is reliably and efficiently scanned by enabled consumer phones, associated mobile devices, retail barcode scanners and computer vision systems.

With HP Link, Digimarc Barcode can carry an SGTIN, the combination of a GS1 GTIN and a unique serial number of up to 12 digits. This provides each package with a unique identity and the ability for consumer brands to track and trace a package or product at the item level through the supply chain all the way to point-of-sale. HP Link offers a security serialisation option including Digimarc Barcode and a toolset that integrates with existing enterprise resource planning (ERP), manufacturing, scanning, distribution and digital printing systems.

By monitoring scanning behaviour and tracking data, the HP Link platform automatically identifies suspicious behaviour, including diverted packages. Cloud-based product and tracking information can be applied throughout the supply chain through to the end consumer.

Heidi Dethloff, vice president of marketing at Digimarc, said: ‘Traceability initiatives are being fuelled by product fraud, recalls, regulatory compliance and the need for greater transparency across the supply chain. This new digital capability from HP allows brands to free-up their package design real estate, while also leveraging the full benefits of variable data printing for connected, customised, personalised and serialised packages.’

Marvin Gross, head of emerging solutions, HP Graphics Solutions Business, said: ‘With HP Link and Digimarc Barcode, consumer brands can protect their brand, track products from origin-to-destination, provide personalised content and coupons, and other benefits. Our solution can integrate with enterprise systems to manage inventory at the unique item level as well as enable faster and easier forms of checkout, including traditional, mobile and self-checkout.’

EFI and Duplo have established a time-saving integration between EFI Fiery digital front ends (DFEs) with workflow automation software and Duplo’s Raised Spot UV Coater – a new collabor...

January 29 2019

EFI and Duplo have established a time-saving integration between EFI Fiery digital front ends (DFEs) with workflow automation software and Duplo’s Raised Spot UV Coater – a new collaboration that streamlines prepress job preparation, saving time while reducing errors and waste.

EFI and Duplo customers can now complete seven manual file preparation steps in one step, including creating separate CMYK and spot UV files, page impositioning, applying of registration marks and barcodes, and submitting CMYK and spot UV files to a Fiery Driven printer and the DDC-810, respectively. The Fiery integration also leverages existing Duplo barcode support implemented earlier this year for additional finishing on Duplo DC-746 or DC-646 Slitter/Cutter/Creasers. Print service providers can save up to 70% of the finisher setup time by using a barcode produced by Fiery Impose software to automate the setup.

“EFI has dramatically reduced the number of manual steps required for preparing spot UV files,” said Anthony Gandara, product manager at Duplo USA Corporation. “Our collaborative efforts will allow our customers to be more efficient during prepress with print and spot UV files correctly prepared for accurate finishing.”

“By choosing EFI Fiery DFEs, today’s print service providers can better differentiate themselves. One of the key benefits is the ability to offer high-value jobs with raised spot UV coating through this new integration,” said John Henze, vice president of Fiery marketing and sales, EFI. “Together, EFI and Duplo continue to improve workflow automation from prepress through finishing. This enables print service providers to work more efficiently and reduce workflow bottlenecks, allowing them to produce a broader range of jobs customers want at a much lower labor cost.”

This new integration is available now for customers with Fiery DFEs and JobFlow software and the DDC-810 Raised Spot UV Coater.

Massivit 3D Printing Technologies, the leading provider of large format 3D printing solutions, in partnership with Marie 3D – large format 3D printing specialists– and renowned car desi...

January 29 2019

Massivit 3D Printing Technologies, the leading provider of large format 3D printing solutions, in partnership with Marie 3D – large format 3D printing specialists– and renowned car designer, Takumi Yamamoto, will unveil the world’s first 3D printed, full-scale concept car. The tribute to David Bowie will be a star attraction at this year’s prestigious Festival Automobile International (FAI) taking place in Paris from January 31 to February 3.

FAI President, Rémi Depoix, said: “It is the first time in our 34-year history that we are exhibiting a full-scale car that has been entirely produced with 3D printing. Yamamoto’s concept car demonstrates immense creativity. We were keen to support this project and present the car almost as a piece of art, very much like a sculpture. I am very impressed with this new technology. It opens up new opportunities in terms of creativity and design for the automotive industry.”

Takumi Yamamoto, designer of the esteemed GT by Citroen and a former leading designer at the PSA Peugeot Advanced Design Studio, is the creative force behind this concept car which is a consummation of his life-long passions for car design and David Bowie.

Paris-based Marie 3D identified that 3D printing was the only feasible production method for implementing the concept car due to its capability to produce complex and creative geometry forms. Traditional manufacturing methods, including CNC routing, would have proven limited in terms of realizing Takumi Yamamoto’s vision. Furthermore, 3D printing turned out to be more cost-effective, having a faster production speed and less waste production.

The car has been 3D printed on Marie 3D’s Massivit 1800 large format 3D printer. The company has an established standing in the automobile industry and this innovative project, leveraging Managing Director Philippe Marie’s expertise in prototyping as well as his timely adoption of a Massivit 3D printer, has paved the way for an entirely new approach to producing concept prototypes.

This new concept prototype production method has provided the perfect expression of Yamamoto’s imaginative and emotive dream to build a David Bowie-inspired concept car that embodies Bowie’s key personal and physical traits. The design incorporates a core body that represents and ‘protects’ the inner Bowie while the intricate, outer body is designed with different looks from various perspectives in homage to the singer’s chameleon-like personality. Crystals were chosen to reflect the purity of Bowie’s lyrical and musical message.

Marie 3D’s Managing Director, Philippe Marie, said: “This was an exciting challenge combining a work of art with a prototype. We especially enjoyed the fact that this is the first project that has allowed us complete creative control, independent of serving a car manufacturer. We have made the most of this total creative freedom. We embarked on the project to demonstrate the capabilities of our Massivit 3D printer in terms of size, speed and reliability. This technology provides a faster and significantly more cost-effective alternative to the conventional processes, supports design creativity, geometric freedom and smoother production.”

He added: “This concept car exposes a completely new method and capabilities for prototyping through 3D printing. Our goal now is to expose the possibilities to the automotive world.”

Amir Veresh, VP Business Development and Marketing at Massivit 3D, confirmed: “This project highlights how Massivit 3D’s large format 3D printing technology facilitates fresh opportunities for scale 1:1 concept prototyping and is sure to fuel the imagination of tomorrow’s car designers and manufacturers. We are absolutely thrilled to partner in this inspirational project.”

Other important players in the project include Cyrille Ancely and Alexandre Larnac.

Industrial designer, Cyrille Ancelly, worked on bringing Yamamoto’s dream to life by developing the design and transforming the concept into a 3D model. CG artist, Alexandre Larnac, turned the concept car’s screen-based 3D model into realistic renderings and animations giving the impression that the car was actually driving on the road.

Find out all about the project on the Massivit 3D YouTube Channel.

Heidelberger Druckmaschinen AG (Heidelberg) is looking to further improve its market position in the growing packaging printing segment by taking its long-standing sales partnership with Masterwork...

January 29 2019

Heidelberger Druckmaschinen AG (Heidelberg) is looking to further improve its market position in the growing packaging printing segment by taking its long-standing sales partnership with Masterwork Group Co., Ltd. (Masterwork), China’s largest manufacturer of die-cutters and hot-foil embossing machines, to a whole new level. Based in the Chinese city of Tianjin, Masterwork is to obtain around 8.5 percent of the Heidelberg share capital under a cash capital increase from authorised capital excluding shareholder subscription rights. The implementation of such capital measure is subject to approval by Heidelberger Druckmaschinen AG's supervisory board.

The proposed capital increase provides the opportunity for Heidelberg to acquire a further strategic anchor shareholder with a long-term investment horizon as well as to strengthen its equity. Subject to approval by the relevant bodies on both sides and the Chinese authorities, the capital measure should provisionally take place by the end of the first calendar quarter of 2019. The issue price of the new shares is set to be EUR 2.68. If the market price significantly outstrips the envisaged issue price, this will be renegotiated in line with statutory requirements. The funds Heidelberg generates with the capital increase are to be used to accelerate its digital agenda (digitising products, processes, and business models, for example) and for general business financing. Masterwork supports the Heidelberg strategy and is demonstrating its clear commitment to long-term collaboration. Heidelberg is currently considering and discussing whether it will seek to obtain a shareholding in Masterwork.

“The Heidelberg Management Board and Supervisory Board are delighted that our long-standing, successful collaboration with Masterwork is to become much closer. This opens up further potential in the growing packaging printing segment, especially in China – the world’s largest individual market. We are expecting better capacity utilisation at our plants across the globe to make us far more efficient, but I would like to stress that this will not weaken our sites in Germany. We are delighted that in Masterwork we are obtaining another long-term investor that firmly believes in the company’s innovative prowess, strategy, and potential for the future,” comments Heidelberg CEO Rainer Hundsdörfer.

“Heidelberg is our ideal partner for jointly leveraging growth potential in the packaging printing market. The stake we are obtaining in this long-established company and world market leader underlines that we are in it for the long haul and are confident Heidelberg has adopted the right strategy,” says Masterwork President Li Li.

Building on leading market position in growing packaging printing segment

Heidelberg and Masterwork, which is listed on China’s Shenzhen stock exchange, have operated a close postpress partnership for a number of years, turning print products into folding cartons for the packaging market. They also benefit from a long-standing, successful sales collaboration. Masterwork specialises in postpress equipment for the folding carton industry. Back in 2014, it acquired the postpress packaging technologies of Heidelberg, which retains responsibility for global sales and digital customer relations. The possibility of linking Masterwork’s postpress machines to the Heidelberg cloud is a big advantage when it comes to realising the value proposition of using production data to boost customers’ productivity. Packaging printing is expected to enjoy above-average growth in the coming years. Heidelberg already holds a leading position in this segment in Europe and the Americas, while Masterwork is one of China’s leading postpress suppliers for packaging. The closer ties are set to significantly strengthen this position in China – the world’s largest packaging market – and in other regions, too.

Creating shared value and stepping up sales of Heidelberg products in China

What’s more, there are plans for closer collaboration focusing on the two companies’ value chains. Heidelberg will continue to supply the dynamic markets in China and the rest of Asia from the site in Qingpu, near Shanghai, that it established back in 2006. As a result of the closer working relationship with Masterwork, it will also benefit from joint component manufacturing operations at the Masterwork site in Tianjin in the future. This will provide both companies with a whole host of possibilities for improving their efficiency.

Supporting an ideology of "New technology for creating the next generation of digital printing," MIMAKI ENGINEERING promotes "Surfac...

January 29 2019

Supporting an ideology of "New technology for creating the next generation of digital printing," MIMAKI ENGINEERING promotes "Surface Imaging", which is a premium added-value printing technology that pushes the known boundaries of graphic expression beyond that of ordinary UV inkjet printers. Metallic expression that uses glitters and foils is a special technique that provides a luxurious and exclusive effect to the printed product. However, it imposes an extra workload on the operators since the metallic process must be handled manually after printing.

By mixing a special bright pigment into the ink, the newly developed UV-curable metallic ink "MUH-100-Si" is able to place UV metallic ink directly on the product without the need for a separate glitter or foil transfer process. Another plus is that applying the in-house printing technology created by the "Surface Imaging" makes available decorative options such as printing both gloss and matte tones, texture expression with embossing effect, and colour metallic expression by printing colour ink overlaid on metallic ink. These provide higher added value to the customer's printed product.

This new ink can be used in a wide range of applications since it is possible to print with UV metallic directly on items such as paper containers and films in addition to a very small lot of novelty items, miscellaneous goods and other formed products.

Main characteristics

1. MMC (Mimaki Metallic Control) printing technology to print both gloss and matte tones

MMC (Mimaki Metallic Control) that prints both gloss and matte tones with one type of metallic ink was created by expanding on the clear ink selective printing technology developed in-house by MCC (Mimaki Clear Control). The range of expression can be expanded according to the application by selecting the beautiful gloss tone print with a shiny mirror finish or a matte tone print that gives a glistening effect by irregular light reflection while limiting the shiny glitter tone.

2. Texture expression with embossing effect

Texture expression is easily printed by changing the ink jet concentration since the ink is instantly cured by UV light when applied to the printing object. The texture expression whose appearance changes according to the light reflection provides a vastly higher level of performance appeal.

3. Full-colour metallic expression

Colour metallic expression is possible by printing with coloured ink on top of metallic ink. The range of expression can be expanded to a nearly unlimited degree by combining the application of metallic, colour and colour metallic according to the design.

4. Printable on wide range of materials using UV-curing inkjet

The most outstanding feature of the UV-curing inkjet printer is that it is printable on widely diverse materials since it cures ink by instantly exposing the ink to UV light when the ink is applied to the object for printing. Conventional analog printing had issues such as being printable only on specific materials such as paper and film. Moreover, the unit cost is high when the lot quantity is less than a certain amount. MUH-100-Si will give a high added value to novelty goods and ordered goods, and drastically widen the scope of customer business since it is printable on a wide range of materials and there is no change in unit cost even in very small production lot.

“This new release LED UV-curable metallic ink, named MUH-100-Si, will be available February 2019," said Brad Creoghton, National Marketing Manager, Mimaki Australia. "The new ink strengthens Mimaki’s product offering and pushes the boundaries of graphic expression beyond that of ordinary UV flatbed inkjet printers. The ink is compatible with Mimaki’s UJF-7151plus printer, which produces high-quality print for an impressive range of industries, from gifts, novelty items and industrial type printing applications. The new ink demonstrates how digital print enables creative ideas to be realised highly efficiently in the product manufacturing process. Whilst metallic effects can generally require further processing, Mimaki’s new technology can be used to produce impactful prints without cost or time restraints.”

www.mimakiaus.com.au

EFI revealed its latest digital front end (DFE) technology for advanced, high-end digital print production. New EFI Fiery FS350 Pro software will give graphic arts professionals more power, product...

January 29 2019

EFI revealed its latest digital front end (DFE) technology for advanced, high-end digital print production. New EFI Fiery FS350 Pro software will give graphic arts professionals more power, productivity and versatility in digital printing. The new Fiery offering – which EFI showed for the first time this week at its annual Connect users conference in Las Vegas – will be available starting this quarter in high-end production DFEs for EFI partners’ new, advanced digital printers and presses.

“With this new platform release, we are continuing to stay ahead of market requirements, ensuring that customers can be as productive and versatile as possible,” said John Henze, vice president of Fiery marketing and sales, EFI. “Fiery FS350 Pro delivers unrivalled productivity from prepress to finishing across a wide range of digital printing engines, plus it provides even better colour results for high-value print products.”

This versatile DFE software offers new features in the key areas that print customers care about: colour and imaging, productivity, management tools and connectivity. New DFEs based on EFI Fiery FS350 Pro software will drive digital printers and presses from several leading manufacturers, across sheetfed, high-speed continuous feed, B1 folding carton, and corrugated digital production systems, including both toner and inkjet technologies. Canon will be the first to launch a new DFE featuring Fiery FS350 Pro in the near future.

The new release also will help customers better manage their print production, using the industry’s most intuitive and integrated DFE offerings, including the ability to establish automated, bi-directional communication and integration with EFI’s market-leading MIS/ERP and web-to-print products. Users also can unify production operations for all Fiery Driven printers – including wide-format and superwide-format inkjet printers – from a single EFI Fiery Command WorkStation interface.

Leading-edge technology for advanced digital print efficiency

FS350 Pro, Fiery Command WorkStation and additional Fiery workflow products for the new DFE software offer a range of production enhancements and advantages including:

The new year is finally here, and with it, lots of chances to capitalise on trends to grow your sublimation business. Among them are a stable of trending products and designs that sublimation produ...

January 29 2019

The new year is finally here, and with it, lots of chances to capitalise on trends to grow your sublimation business. Among them are a stable of trending products and designs that sublimation product decorators can leverage for increased sales throughout the year.

“In 2018, we saw a range of trending substrates and applications that have generated enormous buzz and excitement among product decorators,” said Jimmy Lamb, manager of education for Sawgrass. “Among them are sublimation transfer papers for cotton fabrics and dark colours, substrates that can stand up to outdoor environments, all kinds of creative new drinkware and a renewed focus on home décor.”

Here is a look at some of the trending products Lamb recommends for product decorating businesses to explore in 2019.

• Sublimation on Cotton and Darks

Sublimation for cotton fabrics has long been a missing piece of the puzzle for product decorators. However, last year, several transfer paper products hit the market that enables those with a sublimation system to print and transfer their digital images to cotton. New transfer media offerings from PrintLAT and FOREVER, along with new Virtuoso Print Manager settings for each, deliver impressive results.

In addition to these new papers that enable sublimation to cotton, there are also new twill and flock media options from Chemica and Poli-Tape that enable customers to create transfers for use on dark and cotton fabrics. This media enables you to print directly onto the flock or twill with your Virtuoso printer and Virtuoso Print Manager, use a plotter to cut around the design and then heat set the transfer to the fabric. Within this process, your designs sublimate for permanent coloration and the final transfer adheres to the surface of the fabric.

All of these transfer media options open up new worlds of products that you can offer your customers – and on their favourite fabric. These are a must-try and a massive opportunity for increasing sales in 2019.

• Outdoor Applications

The effects of UV light have inhibited recommended use for sublimated signage or other products for use outdoors. Unisub and ChromaLuxe, really moved sublimation applications forward in 2018 with their lines of outdoor products.

All year, we saw an upswing in the number of products that sublimation businesses offered – everything from outdoor business and event signage to garden stakes, yard signs and decorations, outdoor art installations and home placards.

These will be especially popular come spring and summer for yard decoration, in addition to year-round applications for art installations, exhibits, business and organisational signage, and advertising.

• Drinkware

The entire drinkware segment is incredibly popular right now. One reason for this is the demand for double-wall vacuum-insulated tumblers, which keep beverages piping hot and frosty cold for hours on end. We are also seeing many of new types of drinkware, such as clear and frosted mugs, steins and shot glasses, metallic coatings and even coated stemless wine glasses and growlers (holds up to 64 oz of draft beer).

This growing diversity of drinkware offers many opportunities to creatively bundle products for your customer base or break into the craft brewery/restaurant market. Either way, these are great substrates to try out, build samples of and use to drive new sales.

• Sublimated Décor

There are a number of opportunities to offer sublimated products meant for turning a house into a home. You can use your system to decorate baby and throw blankets, sequin pillows and faux-textured pillowcases, welcome mats, hand towels, key and jacket hangers, and many other items people will love to have in their homes – or give as gifts! Even if you have a smaller printer – SG400 or SG800 – you can use multiple transfers and presses to imprint larger products, such as blankets and doormats.

What’s even better with items for home décor is that there is often demand for personalisation, which gives you the opportunity to set premium prices. It costs little to add a name or photo to a product, but customers pay more for the value delivered.

Digital Ink Sciences Announces New Dye Sublimation Ink for Wide-Format Textile Printers Digital Ink Sciences announced two new ink formulations designed to solve the common yet vexing ...

January 22 2019

Digital Ink Sciences Announces New Dye Sublimation Ink for Wide-Format Textile Printers

Digital Ink Sciences announced two new ink formulations designed to solve the common yet vexing problem of nozzle dry-out within the aqueous dye sublimation market. The new ink formulations allow the printhead to remain off the capping station dramatically longer than traditional inks.

The DIS1000 and DIS3000 series inks are breakthrough formulations, available in both a mid-viscosity and high-viscosity variety. Their unique technology and chemistry boasts the longest decap time in the industry.

Digital Ink Sciences has a reputation for developing water-based textile inks that create vibrant colours with short cure times while also saving on maintenance costs. The newest ink formulations are specifically well suited for wide-format dye-sublimation printers.

The DIS1000 Series is a Mid-Viscosity ink designed for Epson and Mimaki printheads.

Epson:

DX5, DX6, DX7, 5110, 77, 79, 97

SC-S70680, 50680, 30680, F5080, F7080, F718

SureColor F6200, F7200, F9200

Mimaki:

JV2, JV22, JV3, JV4, JV5

The DIS3000 Series is a High-Viscosity ink designed for:

SEIKO, RICOH, KYOCERA, STARFIRE, KONICA

Grant French, Business Development Manager for Digital Ink Sciences, said: "The 1000 and 3000 series ink sets are surpassing our highest expectations for dye-sub transfers. We're getting beautiful vibrant colours, deeper blacks, and excellent jettability with no clogging or misdirected nozzles.

French says the DIS1000 and DIS3000 inks can even reduce head travel time and save ink costs on wide format runs. "The extremely long decap time means you don't have to print those end of line full-colour bars on wide prints," he said.

The ink sets require fewer head cleanings and flushes, which means operators can keep the machines running longer.

Additional Benefits:

Ink Stability

Better "Jetability"

Maintains Nozzle Integrity

Lower Maintenance

Faster Cure Times

Incredible Blacks

Wide Colour Gamut

Improved Wash-ability

Print Durability

Flexibility

Both inks feature faster cure times. Reduced cure times increase bottom line profits on every print.