Morgana Systems Ltd, Milton Keynes, a Plockmatic International company, announces the release of a new member of its DigiFold line-up, the DigiFold Pro XL creasing and folding machine. ...

May 31 2021

Morgana Systems Ltd, Milton Keynes, a Plockmatic International company, announces the release of a new member of its DigiFold line-up, the DigiFold Pro XL creasing and folding machine.

The DigiFold Pro XL is the latest addition to the Morgana DigiFold family. The machine is developed from the well proven Morgana DigiFold Pro and is equipped with the latest version of the patented DynaCrease creasing system. The unit incorporates a suction feeder that handles stock sizes from 210mm to 1,300mm in length. The heavy-duty automatic creasing and folding system is designed to complement mid to high volume digital and offset production presses.

Morgana DigiFold Pro XL fits perfectly with the long-sheet capabilities of today’s production printers by featuring a pull-out extension that handles sheet sizes up to 1,300mm as standard. This opens the door to new applications, such as landscape booklet covers, book covers for oversized perfect bound books, multi-panel brochures, and the many other applications made possible by long sheet presses.

The DigiFold Pro XL is equipped with the latest version of Morgana’s DynaCrease, where the creasing blades can now be easily changed without the use of tools. An additional Static Crease option can be installed to enable different crease profiles to be applied in one pass, commonly used in the production of “hinge and spine” creases in book covers. Changing the Static Crease blade for a perforation tool will provide the full range of crease and perforation options, such as tear out coupons and reply cards.

Morgana’s DigiFold Pro XL can fold up to 6,000 A4 sheets per hour, and in crease-only mode it can produce up to 7,500 sheets per hour. The unit has a maximum loading capacity of 200mm.

The top-fed vacuum feeder ensures stable production for long runs. Morgana’s user-friendly operator panel allows for the simple input of sheet size, media type, and thickness. With this information the Pro XL can automatically set the speed, roller gap, and fan settings.

A unique air-knife system is used for sheet separation. Full cross perforation is available, plus up to five inline perforation/scoring wheels. The unit can produce up to 30 creases per sheet (Static Crease). It is equipped with both a belt-stacker for folded sheets and a delivery tray for crease only jobs.

The loading and unloading areas are an open design to make it easy to monitor performance and make changing from job to job fast and efficient. The new open feeder design is capable of efficiently feeding a wide range of media types and weights. It is equipped with automated vacuum feed technology, specifically designed to handle the widest range of pre-printed media.

Commenting on this latest addition to the Morgana range, Ray Hillhouse, VP Sales & Marketing said: “The Pro XL is an important addition because of its wide stock range. We work closely with the print engine manufacturers on several levels. All of them were pushing into longer sheet applications with their latest print engines. As well as opening up a new range of possibilities, we’ve made the DigiFold easier to operate and automated much of the feeder set-up with our new vacuum feeder.”

Full details of Morgana’s product line-up can be found at: www.morgana.co.uk

BOBST has updated the design of its digital label press to improve convenience and usability, helping to make this highly productive machine even more efficient. Design updates include...

April 20 2021

BOBST has updated the design of its digital label press to improve convenience and usability, helping to make this highly productive machine even more efficient.

Design updates include a more ergonomic and easier-to-access ink cabinet, the possibility to fit rolls up to 600mm for ultimate substrate versatility and a flexible / movable screen for an even more convenient management and control of the machine from every angle.

“One of the hallmarks of BOBST is we never sit still, we are always thinking of ways we can improve the customer experience,” said Erik van Sloten, Head of Sales, Labels. “And the way we do that is by first and foremost listening to our customers. The changes we have made to the Mouvent LB701-UV have come from speaking to printers and converters, understanding their needs, and acting on them.”

The Mouvent LB701-UV enables digital label production for ultra-short and medium run label jobs, with no trade-offs. It is associated with very high productivity, with a speed of up to 70m/min, exceptional print quality (1,200 x 1,200 dpi), and the widest color gamut in its category – printing with up to 6 colors plus optional white with 70% opacity, at 45m/min.

The machine already had a compact and ergonomic design, but this has been enhanced further ensuring one operator only is able to run the press.

“It’s by watching that you design optimal efficiency,” explained van Sloten. “By making the design as user-friendly as possible, we provide the operator the means to complete the tasks at hand.”

The machine provides the best TCO (Total Cost of Ownership) in its category. Elements contributing to its excellent TCO include low initial investment, ongoing operational costs, quick set-up time and high productivity, allowing for higher profitability.

Danish converting equipment manufacturer Grafisk Maskinfabrik has launched LR250, an entry-level label inspection rewinder, featuring a built-in missing label detection system. The new...

April 06 2021

Danish converting equipment manufacturer Grafisk Maskinfabrik has launched LR250, an entry-level label inspection rewinder, featuring a built-in missing label detection system.

The new label inspection rewinder offers a built-in sensor for missing label detection. For more demanding applications, such as pharmaceutical labels, the LR250 can be configured with a video camera for 100 percent advanced print inspection and verification.

‘The LR250 is a versatile machine with some innovative built-in features that will ensure all your rolls are delivered in top condition with all labels present and correct,’ said Uffe Nielsen, CEO of Grafisk Maskinfabrik. ‘We have developed the rewinder with different inspection options, so there is a version that suits every budget without compromising on quality.’

The LR250 can process label rolls up to 250 mm (9.8in) wide at a production speed of 200 m/min (656 ft/min). It comes with a two-way rewinding capability, integrated web guide, and a label counter as standard. The adjustable splice table features pneumatic splice clamps and can be fitted with a splice detector.

The missing label feature stops the machine upon detection, calculates the error position, and reverses the web until it is aligned with the splice table. Once the missing label has been replaced, the web is re-checked, and the rewinder completes the job at full speed.

The option to integrate a video camera upgrades the machine's capabilities to include a full print quality inspection. GM has partnered with BST-Eltromat and Nikka Research to offer 100 percent quality inspection for printed labels. The camera will be connected to an external system, which checks the print for faults and verifies it against the master PDF file.

The LR250 has further been developed with tension separation for working with thin, sensitive materials and PET liners. Thanks to the centrally placed nip roller, the web can be unwound with one tension and rewound with a different tension to avoid stretching the material. A capacitive sensor for clear-on-clear labels can further extend the range of materials that can be processed.

There is space for a full UV inkjet printer for coding and marking for customers requiring variable data. GM partnered with Domino, Markem-Imaje, and Rea Jet, but other manufacturers' systems can also be fitted on demand.

‘As fault-free label production has become the norm, our customers want machines that enable them to deliver perfect rolls of labels to their customers, every time,’ added Nielsen. ‘This little label inspection rewinder is the perfect solution for that, but don’t let the size fool you. We have built the LR250 with so many clever options that it can grow with our customers’ business and tackle a wide range of label requirements.’

Epson has taken delivery of and installed Australia’s first high productivity SurePress® L-6534VW industrial UV digital label press at their new Experience Centre in Yennora, Sydney.

March 24 2021

Epson has taken delivery of and installed Australia’s first high productivity SurePress® L-6534VW industrial UV digital label press at their new Experience Centre in Yennora, Sydney.

The new SurePress L-6534VW prints at speeds of up to 50 meters per minute for higher productivity with improved reliability and usability.

It also uses wide gamut CMYK inks with a high opacity white as standard and includes an innovative in-line digital varnish which delivers smooth gloss, matte and spot finishes.

The L-6534VW label press combines Epson PrecisionCore® printheads around a central impression drum in conjunction with a narrow platen gap, delivering precise droplet placement without web meandering or skewing. Its LED pining system also helps deliver finer tonal gradation and sharp images.

Epson’s proprietary Nozzle Verification Technology (NVT) and automatic head maintenance efficiently help the L-6534VW label press print through each shift without operator intervention.

As the L-6534VW label press supports a wide range of label applications including food and beverage, the labels it produces are also weather resistant.

Standard features for the L-6534VW include corona treater, web cleaner, ioniser and additional UV curing kit for increased ink adhesion on difficult substrates, all of which combine to help the press provide the highest level of versatility in print production.

More detail on key features of the L-6534VW

PrecisionCore linehead

The PrecisionCore linehead is the key behind the high performance and reliability of the SurePress L-6534VW. Each of the six lineheads are comprised of PrecisionCore print chip modules (printheads), delivering precise quality with accuracy and high resolution. Smooth and natural gradation and colour tone,

from highlight to shadow, can be reproduced with 600 x 1200 dpi resolution using a minimum droplet of 3 picolitres and Variable Sized Droplet Technology.

High Productivity

Epson's PrecisionCore linehead, highly accurate web feeding technology and Epson-developed UV ink enable high-speed printing up to 50 m/min with high reliability and reduced down time. The L-6534VW saves you time on every job with its many automated and efficient productivity features.

All LED UV Colour Pinning Control

Epson’s own LED UV pinning system semi-cures and stabilises, controlling ink spread for finer tonal gradation, sharp images and vivid colour. UV light is applied immediately after each colour is printed. This allows perfectly round drops to be placed in their correct positions.

Centre Drum Web Handling

The Drum Platen is a highly accurate web feeding technology which prevents

meandering and skewing of the web. The gap between the printhead and substrate is kept to a minimum, which enables accurate ink placement, for crisp text and fine lines.

Meandering and skewing of the web does not occur, because the substrate is held tightly around the drum. In comparison, the camber type platen of other presses requires manual adjustments when the substrate is changed, in cases such as Y-direction skew adjustment and colour adjustment (substantial waste of substrate). The SurePress registration adjustment is electronic.

The substrate is “fixed” to the drum, as it passes all printhead colours, hence it provides excellent colour-to-colour registration.

Nozzle Verification Technology and Auto Head Maintenance Function

Nozzle verification technology is an automatic nozzle check system with advanced ink droplet detection technology. A drive signal is sent to the piezo actuator. The same piezo element is used as a sensor to measure the pattern of the residual vibration. The residual vibration is analysed in milliseconds, reporting the nozzle status. All nozzles are checked after cleaning and before printing. A manually printed nozzle check pattern is not required to check if a nozzle is firing.

Auto head maintenance cleans the nozzles automatically to eliminate manual cleaning during each shift. It is fully automatic with no operator intervention required. Wash fluid is sprayed on the head surface and then the head is cleaned

automatically with the cleaning wiper. The auto self-head maintenance function cleans heads periodically to avoid nozzle clogging based on print duty cycle and results of the nozzle verification test. After maintenance, the press returns to printing again with no operator interaction or interruption in job sequence.

SurePress Customer Support Service by Remote Monitoring System

The operational status of the SurePress is monitored using a remote monitoring server. The L-6534VW has an extensive network of sensors which feed into a diagnostic system. This allows, at any time, a quick response and predictive

analysis, all done in advance of a repair visit.

Inline Digital Varnish

The L-6534 has the Epson innovative digital varnish ink. A gloss or matte finish can be printed selectively as a varnish. High value and very appealing accents can be added to lift the visual appearance of specific areas. The different finishes are achieved by changing the way the digital varnish is jetted from the printhead. Brand owners now have digital flexibility with spot varnishes. Digital varnish delivers smooth and even gloss, matte and spot finishes. The auto gloss varnish control function enables the appropriate amount of digital varnish to be applied to select areas according to the amount of WCMYK ink. This achieves a smooth, even and glossy finish.

High-Opacity White Ink

The single-pass high-opacity white ink provides high-density performance equivalent to screen printing and the ideal base layer for printing vivid colour on clear or metalised substrates. The bright white ink also gives the ability to print opaque, fine text and lines, even when printing clear labels for clear packaging. It offers the flexibility to print white on top of colours.

Clear film can be printed with colour ink first, followed by white ink using a printing method that allows you to view the results from the back of the film (reverse printing).

Reverse Print

L-6534VW has a function to rewind the substrate. To print white over colour (reverse print) on clear film, you can rewind and print without replacing (returning rewind to unwind manually) the roll. Waste of substrate is reduced by resuming printing after proofing by simply rewinding and resuming printing.

Epson SurePress Inks: Food Contact Materials (FCM) Compliance

Epson label inks reach major milestones in Food Contact Materials compliance. Epson inks used in SurePress inkjet label presses are compliant with EU Regulation framework (FCM EC No. 1935/2004), Good Manufacturing Practices Regulation (GMP EC No. 2023/2006), Plastics Implementation Measure Regulation (PIM EU 10/2011) and included in Swiss Ordinance (SR 817.023.21) on Food Contact Materials for food packaging printing inks.

Wide Gamut

A high concentration of pigment particles and UV pinning, which prevents ink drops from spreading or deforming, enables wide gamut and vivid colours. Wide gamut enables the reproduction of a wide range of desired colours that brand owners require. The gamut volume of L6534VW is larger than printing standards of offset coated paper like FOGRA, GRACoL and Japancolor.

You can get a demonstration of the new SurePress L-6534VW industrial UV digital label press at Epson’s Experience Centre in Yennora by contacting Epson Australia here.

Portuguese converting equipment manufacturer Lemorau has launched its latest MEBR+ Evolution, a printing and finishing machine developed to produce premium labels with a flexible, modular configura...

January 26 2021

Portuguese converting equipment manufacturer Lemorau has launched its latest MEBR+ Evolution, a printing and finishing machine developed to produce premium labels with a flexible, modular configuration.

The Evolution features Lemorau’s latest and most advanced technologies combined with state-of-the-art components. It includes an unwinder equipped with a nip in servo, web guide, and splice table with space to include web cleaner and corona treatment, a flexo module in registration, as well as a flat screen-printing module that produces a glossy or matte UV varnish, glitter, rough and metallic effects.

The MEBR+ Evolution also includes hot foil stamping for adding metallic effects and a finishing module with a semi-rotary/rotary die-cutting unit equipped with an anvil roll with adjustable gap and an easy strip G2 waste rewinder, air trim removal followed by the slitting and double rewinding.

The machine is fully flexible and enables converters to add and change its modules to respond to the demand. The long list of optional equipment includes a rotary die station, anti-static bar, booklet label module, digital printing module water-based CMYK, UV inkjet option between four and six colours, just to list a few.

‘For the last few months, we have been working very hard to develop this new project not only to complete our machine portfolio but also to open new market segments with the two new options of flat screen printing and hot stamping,’ said Pedro Teixeira, CEO of Lemorau. ‘This project was totally focused on label producers that aim to manufacture high-quality labels with embellishment effects from rolls provided from offset or digital presses. I think it is an ideal machine for label producers focusing on premium labels market segments such as wine, cosmetics, and spirits.’

Mark Andy has launched Evolution Series E3, the second iteration of its Evolution Series flexo press, which initially debuted at Labelexpo Europe in 2019. The newest press has been developed to fil...

December 15 2020

Mark Andy has launched Evolution Series E3, the second iteration of its Evolution Series flexo press, which initially debuted at Labelexpo Europe in 2019. The newest press has been developed to fill a gap in the market for a servo powered machine that prioritises ease of use and reduces operating costs.

The original Evolution Series flagship press is being rebranded to Evolution Series E5. This machine provides converters a scalable production technology designed to provide adaptability to future business growth needs. In its first year, 46 Evolution Series presses have been installed worldwide.

The new Evolution Series E3 is available in 13 and 17in (330 and 430mm) web widths with production speeds up to 500 ft/min (150 m/min). Evolution Series E5 maintains its technical specifications and is available in 13 and 17in (330 and 430mm) web widths with production speeds up to 750 ft/min (230 m/min).

According to the company, even with the Evolution Series E5, there was still a market for a more accessible full-servo flexo press for converters focused on producing quality labels affordably.

‘When we came to market with Evolution Series, now known as Evolution Series E5, we intended to provide converters a more attainable solution built on Performance Series technology they could grow with, configure what they need now, knowing they could evolve in the future. And we did just that,’ said Tom Schlembauer, chief business officer for flexo at Mark Andy. ‘But after listening to our customers, we realised there was an opportunity to offer a machine that focuses primarily on getting back to the basics, but with modern technology and affordability. So, we built a solution that allows converters to be competitive exclusively in the prime label market and that solution is Evolution Series E3.’

With the launch of Evolution Series E3, Mark Andy is also introducing Mark Andy ProUV, which will come standard on all E3 presses. Powered by Phidastien’s UV curing technology, it enables high-quality, reliable results. It is a fully integrated curing system, with power and air located on-press and within a single cabinet to help converters maintain a smaller pressroom footprint.

Evolution Series E3 and E5 join Mark Andy’s flexographic portfolio offerings, including the Performance Series P7 and P9. Both Evolution Series machines are available for immediate order.

Scodix has announced the release of PolySense™ 550, a new polymer for digital enhancement developed for the food packaging industry. Compatible with the entire Scodix Ultra portfolio, the pol...

December 07 2020

Scodix has announced the release of PolySense™ 550, a new polymer for digital enhancement developed for the food packaging industry. Compatible with the entire Scodix Ultra portfolio, the polymer is already being used by Italian Folding Carton producer, Packly, to great effect.

Guy Alon, VP of R&D at Scodix, states, “Scodix enhancements create great visual impact for the brands who use them, and food packaging is no exception. The new Scodix PolySense 550 polymer broadens the Scodix portfolio while presenting customers with the ability to further differentiate themselves from the competition – which is crucial on the packed supermarket shelves. The value of adding digital enhancements to food packaging with the assurance that the printing procedure is safe for consumers according to food packaging standards is a big step forward for Scodix Ultra users.”

Scodix PolySense 550 food packaging compliance refers to indirect contact for low migration. Scodix capitalised on its four years’ experience in manufacturing low migration Scodix PolySense™ for the Scodix E106 press – which works daily in the packaging industry. This development was validated by the world renowned SQTS Labs in Zurich Switzerland and was tested and approved according to Swiss Ordinance.

Giuseppe Prioriello, CEO and founder of Packly, states, “Scodix PolySense 550 augments existing Scodix applications with the ability to apply it to food-grade packaging. It is a Packly company priority to guarantee 100 percent safe packaging in the food sector, as well as the other sectors we operate in. We strongly believe that producers must be ahead of the game and provide safe packaging for short runs without waiting for the customer to request the service. This is the reason why we are using this food compliant polymer.”

Prioriello adds, “We are already experiencing an increase in business as brands are personalising their packaging while taking advantage of the shorter runs and faster lead times. With no set-up, no waste and the fast time-to-market, food packaging digital enhancement has just broadened the possibilities for the industry dramatically.”

Phillip Rennell, Sales and Marketing Director at Currie Group said, “Scodix is continuing to innovate to deliver new applications and drive into new markets, which works really well in Australia and New Zealand where our customers are looking for a larger variety of applications in a smaller market place”

Scodix applications that can use Scodix PolySense™ 550 include Scodix Sense™, Scodix Foil™, Scodix VDE™, Scodix Cast&Cure™ and Scodix Glitter™. Types of substrates applicable include offset, HP Indigo ElectroInk and Lamination.

About Packly

Packly is a complete packaging solution for both businesses and graphic designers. Anyone can create and download dielines instantly, view a 3D box in real-time and print high-quality personalized packages in 48 hours. Upload the artwork based on the Packly template to visualize a 3D mock-up in real-time including with embellishment effects. Share the digital proof as an interactive 3D through a simple link to show anyone your artwork on every mobile device. Packly is a fully dynamic web application for packaging. It uses proprietary algorithms which allow generating over 500 billion size combinations. At Packly there is no minimum order: start today with just one box and boost your sales. Read further the Packly blog on enhancement: https://blog.pack.ly/en/gold-or-silver-foil-embellishment-and-spot-varnish-the-new-products/

For further details, contact the Australian & New Zealand supplier, Currie Group www.curriegroup.com.au

anytron (Bitek Technology) a South Korean equipment manufacturer has launched any-JET II, a digital press with in-line finishing options developed for the label and flexible packaging markets.

November 18 2020

anytron (Bitek Technology) a South Korean equipment manufacturer has launched any-JET II, a digital press with in-line finishing options developed for the label and flexible packaging markets.

The new any-JET II, powered by Memjet inkjet printing technology, offers in-line finishing capabilities, 1600x1600 DPI resolution with lamination and custom label shapes and sizes with laser die-cutting. It supports variable printing and cutting speed between 3 and 18m/min (9.8 and 59 ft/min) depending on the label design.

This all-in-one machine also includes a wide range of functions such as over-laminating, laser die-cutting, matrix removal and slitting. It can be additionally utilized for flexible packaging printing and laser scribing for easy opening, microwave steam release feature pouches.

One of the new developments in any-Flow, an integrated workflow and RIP software allowing to control the printer and laser die-cutter with integrated user interface. It extracts cutting lines from printing design and automatically sends this information to the laser die-cutter. Furthermore, the embedded automatic job changeover function enables changing print job automatically by reading a QR code.

‘Anyone interested in making the shift to digital production will be interested in the any-JET II. Not only will it enhance the production capacity, but it will also expand the flexibility of applications,’ said Brian Kim, sales manager of anytron. The idea behind our in-line system is to cut the preparation time by up to 20 percent. This innovative technology eliminates waste and improves lead times, increases flexibility to support personalisation and highly variable applications with just-in-time delivery.’

All stakeholders in the packaging value chain can enjoy an enhanced user experience, with even greater speed and efficiency, now Esko has unveiled its WebCenter 20.0. The latest feature-packed vers...

November 10 2020

All stakeholders in the packaging value chain can enjoy an enhanced user experience, with even greater speed and efficiency, now Esko has unveiled its WebCenter 20.0. The latest feature-packed version of the company’s powerful and secure web-based packaging management and collaboration platform manages all aspects of packaging and label production for brands and their print suppliers.

“With WebCenter 20.0, we set out with a goal of making prepress processes considerably faster while delivering a 25 per cent increase in performance,” said Roman Stepchuck, Product Manager. “I’m delighted to say we have succeeded.”

WebCenter cemented its reputation as the go-to solution in the industry through its ability to streamline approval and project lifecycles, removing bottlenecks that are most commonly associated with the packaging development process.

WebCenter 20.0 includes new and additional support for end-to-end colour workflow for brands and their suppliers – Color Trace. Brand owners can create colour specifications directly in WebCenter and communicate them to their printers, who use ColorCert software from X-Rite to report a scorecard of the final production.

“We’ve also introduced an ‘Ad Hoc Approver’ function,” said Roman. “When users want to send a file for approval, but the recipient is not a user of WebCenter, that no longer matters. In WebCenter 20.0, files can be sent directly to an external email address – they can even be forwarded on to other parties for approval, depending on permissions – saving countless valuable lost hours in the approval process.”

A crucial focal point for WebCenter product development is the overall user experience, including the ease of use for non-expert users. “We wanted to make the user experience even more intuitive and personalised,” said Paul Land, Product Manager. “We’ve essentially designed the latest version of WebCenter to make your workflow more intuitive than ever before.

“With WebCenter 20.0, we have introduced a new dashboard where users can create a personalised view of their activities,” added Paul. “We’re making the complex simple! Having introduced a huge amount of functionality over the years, we’re now enabling users to switch on and off individual features. This will simplify and tailor the experience, ensuring they have easy access and navigation to all the information relevant to them in one place.”

Avatars, similar to those used on social media platforms, have also been included making the experience even more personal. For the first time, users can access and edit all their files from the new single dashboard page. The new Task Assignment function gives users an overview of how busy colleagues are when allocating tasks, helping improve efficiency and manage workload of employees.

“From a user experience perspective, integration with the interactive tools packaging professionals use on a daily basis is also important,” said Paul. “That’s why we have also introduced an impressive extra optional module, the new ‘WebCenter Tasks Plugin’.

“WebCenter was already compatible with Adobe Illustrator,” he explained, “but with the new ‘WebCenter Tasks Plugin’, WebCenter 20.0 is also compatible with InDesign and Photoshop too. In just a few clicks, users can open, edit and upload changes, significantly streamlining the entire process.”

Other additional new modules include ‘Cloud Archiving’, providing almost limitless storage and freeing up valuable space for businesses, and ‘Interactive Text Compare’, a new software tool which checks copy against core data ensuring no issues arise when copying files across.

Available now, WebCenter 20.0 is free to Esko Software Care Plan customers. Anyone wishing to learn more about WebCenter 20.0 can do so by visiting the new Esko Innovation Hub (www.innovation.esko.com) which has been designed to provide users with a unique insight to the Esko Software 20 portfolio of innovations in a virtual environment. Users can navigate around the latest integrated hardware and software solutions from Esko, in their own time, accessing insights and technical information, as well as learn new ways to boost business productivity, efficiency and profitability.

For more on new WebCenter 20.0 from Esko, visit https://innovation.esko.com/en/labels-flexibles/webcenter

Xeikon is delighted to announce the launch of its new Fusion Embellishment Unit – Xeikon FEU. This latest addition to its already broad portfolio of digital equipment for labels, builds on th...

October 05 2020

Xeikon is delighted to announce the launch of its new Fusion Embellishment Unit – Xeikon FEU. This latest addition to its already broad portfolio of digital equipment for labels, builds on the company’s ambition to provide and equip label printers and converters with the most comprehensive portfolio of innovative digital equipment for the broad scope of label print manufacturing. The Xeikon FEU offers label printers and converters maximum flexibility to meet the demands of brand owners and designers striving to achieve high end, eye catching, unique, entertaining and creative labels. With complete digital finishing and embellishment capabilities, Xeikon’s FEU is based on MGI technology and provides UV spot varnish, tactile varnish, foiling, 3D textures and holograms across a wide range of substrates including clear on clear, common BOPP and paper facestock up to natural structured papers. The Xeikon FEU will be commercially available in Europe and North America as from October 2020.

Filip Weymans, Xeikon’s VP marketing says: “In a world of ever-evolving consumerism, we are seeing significant and ongoing changes in behavioural patterns. Consumers are more discerning and brand owners are demanding more from their designers and printers. In packaging and retail, there is increasing pressure for creative innovation and higher levels of productivity. To that end, Xeikon is first and foremost addressing the needs of its customers. We continue to adapt to current trends and with the launch of the Xeikon FEU we are offering our customers maximum opportunities. The workflow integration built around our X-800 Vectorizer will ultimately provide our customers with all they need to effectively move towards total digital label print manufacturing.”

Using Xeikon’s Fusion Embellishment Unit, label printers with an existing portfolio of wine, premium beer, gourmet food, spirits and health & beauty labels will be able to achieve easy and fast proofing of new designs and faster times to market. With no need for tooling and reduced setup times, this economical solution offers superior levels of creative quality finishing on smaller volumes of labels. Using inkjet technology, any defined label area can automatically receive spot UV varnish with or without raised 3D texture effects. Similarly, for foiling applications the digital label area can receive digitally controlled foil with or without raised 3D effects with limited complexity compared to analogue.

Xeikon’s FEU is a stand-alone solution. This enables it to embellish printed materials originating from different technologies. It is also able to pre-print foil onto substrates, thus meeting the many new brand-owner needs for today’s label designs. Optionally Xeikon’s FEU can be equipped with a semi rotational die cut unit so that it will deliver fully embellished and finished labels. Whilst Xeikon’s focus at present is on label applications, the new FEU has the potential to address other applications over time.

Weymans concludes: “Xeikon’s long term goal is to offer its customers the broadest range of products which address the digital transformation of print manufacturing Well established industry partners, like in this case MGI digital technologies, very often haven proven products that integrate very well in this digitisation process. With this latest addition to our portfolio, one of the most important benefits for our customers is the availability of integrated digital technologies – all provided and supported by supplier - which ensure maximum productivity throughout the manufacturing process. The combined provision of digital printing and digital embellishment will enable label printers to run high-end, short to medium sized jobs at substantially reduced costs with a shorter time to market. Xeikon continues to lead the way as a trusted advisor and supplier of innovative digital systems for the global label community.”

/ Masterfully crafted from real cherry wood and cut into thin slices - this process mak...

September 15 2020

/ Masterfully crafted from real cherry wood and cut into thin slices - this process makes every sheet unique and different

/ The natural texture and grain variations in the wood wont effect the print and converting process

/ This face stock easily accepts foil stamping

/ Top coated and optimised for HP Indigo Presses.

/ Designed for premium product labelling on bottles and food packaging (wine, spirits, beverages and gourmet food)

The Sapphire EVO W is the first flexible packaging press to enter the market using Kodak’s latest continuous inkjet technology. Kodak, in partnership with Uteco, has announ...

September 01 2020

The Sapphire EVO W is the first flexible packaging press to enter the market using Kodak’s latest continuous inkjet technology.

Kodak, in partnership with Uteco, has announced the launch of a digital flexible packaging press. The announcement was scheduled to come during drupa 2020.

The Sapphire EVO W is the first flexible packaging press to enter the market using Kodak’s latest continuous inkjet technology. The Uteco Sapphire EVO W press is the second product developed by the Uteco Group in partnership with Kodak for digital flexible packaging production.

The water-based Kodak Prosper Press QD Packaging Inks have been certified for indirect food contact.

Kodak first introduced the new Uteco Sapphire EVO W late last year and intended to officially launch it at drupa. According to the company, the Sapphire EVO W Press is now available globally, and the first installation will occur later this year at a customer in the US.

"The Sapphire EVO W is the first digital packaging press to match the productivity of flexo and the quality of gravure," says Randy Vandagriff, senior vice president, digital print, Eastman Kodak Company. "It uses our high-resolution Ultrastream inkjet technology and QD Packaging Inks to bring the endless opportunities of digital printing into mainstream production of flexible packaging."

The Sapphire EVO can print flexible packaging applications on plastic films and paper. The press prints CMYK inkjet at 600 x 1800 dpi across 49.2" print width at speeds of up to 500 fpm.The press is available with inline priming, flexo-white and post coating and a hot air/IR drying system.

Global printing industry leader Inkcups announces the release of a new feature for Helix® digital cylinder printers: Transparent Pin Curing. Transparent Pin Curing (TPC) is a speci...

August 25 2020

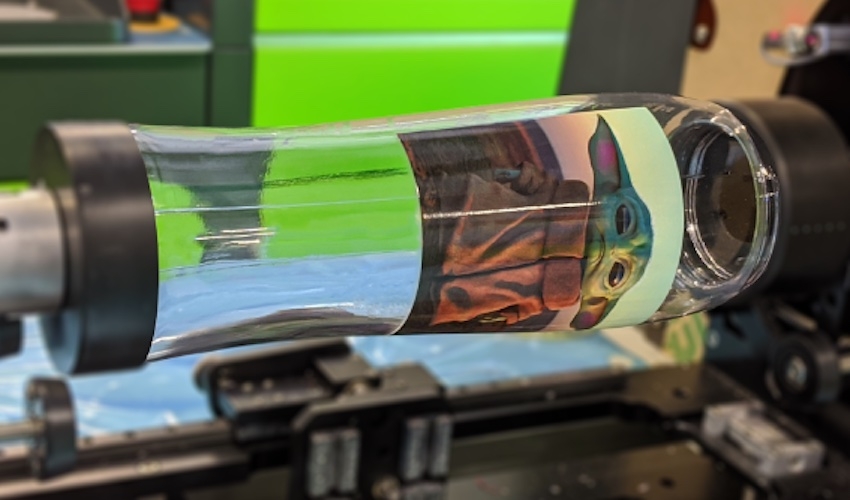

Global printing industry leader Inkcups announces the release of a new feature for Helix® digital cylinder printers: Transparent Pin Curing.

Transparent Pin Curing (TPC) is a specialised system that enables UV inkjet printing on clear products such as plastic bottles, glassware, spirit bottles and wine bottles, without the need to add a UV-blocking agent into the vessel. Traditionally, UV inkjet printing on clear vessels requires a stuffing agent known as a “foxtail” to block the UV light from curing the ink and damaging the print heads. With this new patent-pending technology, containers remain uncontaminated and sterile on the inside and print head life is protected. As an added benefit, removal of this extra step thanks to the TPC system also streamlines the production process.

“We have been developing and testing this new feature for some time and are excited to bring it to market. The revolutionary transparent pin curing system will simplify production, improve efficiency and is completely retrofittable to our fleet of Helix® digital cylinder printers. It makes a significant difference for transparent items,” said Ben Adner, CEO of Inkcups.

The proprietary TPC system is available as a field-upgradable retrofit for existing Helix® printers or on new Helix® machines. These include the Helix® Digital Cylinder Printer and Helix® Hi-Fi Photorealistic Rotary UV Printer, which was released in 2019. Recognised in the industry as very fast and reliable machines, they are ideal for use in print-on-demand, short and medium volume drinkware printing applications. Typical applications include full color imaging on glassware, stainless steel tumblers, plastic bottles and much more.

The TPC system feature is engineered and manufactured in the U.S. and available for order now.

www.inkcups.com

Started in 1945 Action Labels & Nameplates has been heralded for being inventive and forward thinking. 75 years later Action Labels & Nameplates is undergoing a digital transformation under...

August 18 2020

Started in 1945 Action Labels & Nameplates has been heralded for being inventive and forward thinking. 75 years later Action Labels & Nameplates is undergoing a digital transformation under new ownership. New ownership means new equipment such as their recent purchase the highly effective Epson SurePress L-6034VW industrial UV label press.

Action Labels CEO James Malone explained, “Action Labels have a good range of semi rotary and intermittent printing machinery that operate well, however the demand has been increasing for short runs of labels and multiple SKUs and conventional printing machinery is getting less competitive in today’s digital world. So we started looking for a solution and decided the Epson SurePress L-6034VW was ideal.”

For Malone it was important to find a machine that not only could print on a wide range of substrates with durable and lightfast inks but could also print on many different widths of stock from 80mm up to 340mm.

He continued, “After looking at many UV inkjet presses in the marketplace is was soon apparent that there is a lot of similarity amongst the various models. With so many UV Inkjet presses already installed in Australia we needed to find a UV Inkjet press that would make us stand out from the competition. That UV press is the Epson SurePress L-6034VW.”

Action Labels & Nameplates is a label convertor who currently uses a combination of roll to roll letterpress and roll to roll screen printing machinery. Digital printing was done on smaller roll to roll inkjet and toner equipment. Malone has been watching UV inkjet develop in terms of quality and speed over the years and saw the opportunity where a UV LED inkjet solution would give Action Labels & Nameplates the advantage in the growing short-to-medium run durable label markets.

Malone continued, “The SurePress L-6034VW certainly fulfils our requirements and those of the market. It can print on stock widths from 80mm to 340mm wide and the digital varnish station in the final station allows matt or gloss UV varnish effects to be created after CMYK or WCMYK printing. Epson are a multi-billion dollar turnover company so there is significant support and backing from them, they also designed and made the press from the ground up and make their own inks and printheads. These are all big advantages for us.”

The Epson SurePress L-6034VW is a UV LED inkjet digital label press which delivers high quality, productivity and durable labels. The press uses Epson’s own PrecisionCore printheads and comes standard with wide gamut CMYK, high opacity white and digital varnish inks, led curing, corona treater, web cleaner, ioniser, eye mark sensor and an additional UV curing lamp. Everything that’s required for prime label production.

When Malone purchased the SurePress he went on to experience Epson’s service team do an excellent job of having the press installed and operators trained to meet his first UV print deadline.

He added, “The positive feedback of the high quality output due to the colour pinning control and centre drum web handling platen has been great. Also the innovative digital varnish ink printed in one pass gives our brand owners the flexibility of either matte and gloss using spot varnishes to add high value and very appealing accents that lift the visual appearance of specific areas. As a result we are using the SurePress L-6034VW for CMYK printing and durable labels for the lucrative cosmetics, beer and wine markets.”

The Epson SurePress L-6034VW comes with an Adobe Illustrator plugin so it is almost as simple to print with as an office printer. A job is loaded into Adobe Illustrator then all pre-flight, imposition, VDP and colour management is handled by Epson’s Illustrator plug-in software and spot colours and media profiles are controlled by the easy to use touchscreen control panel on the press.

This ease of use is not lost on Malone who commented, “We are very impressed by the high level of engineering that has gone into the L-6034VW. The press is solidly built and has a zero point reverse feature so very little stock is wasted. Adding to Action Labels & Nameplates large range of diecutting, hot foiling and screen printing machinery, the SurePress L-6034VW provides the perfect digital engine to allow us to serve a wide range of industries including superfast turnaround trade printing of labels and tags.”

It’s clear James Malone is happy with his new purchase and equally with Epson’s service and support as he concluded, “The value of having one supplier design and manufacture all the key technologies of a digital label press cannot be underestimated. This, combined with Epson’s excellent local service and support makes this purchase a no-brainer.”

Epson’s UV range of presses is expanding as the company furthers its commitment to providing a printer for all market sectors, needs and requirements. New in their UV range is the SurePress L-6534VW a press that uses Epson’s 600 x 1,200dpi PrecisionCore printheads and produces print speed modes of Production mode 50 m/min, Standard mode 30 m/min, and a 15 m/min High-density mode.

For more on Action Labels & Nameplates solutions contact their general manager Steve Bonanno at sales@actionlabels.com.au and for more information on the Epson SurePress range, visit www.epson.com.au

Durst has announced the official start of beta testing of its new Tau RSCi label press at label converter LabelPrint OÜ. The new single-pass UV inkjet label press, which was annou...

July 20 2020

Durst has announced the official start of beta testing of its new Tau RSCi label press at label converter LabelPrint OÜ.

The new single-pass UV inkjet label press, which was announced at Labelexpo Brussels last year, was installed at its headquarters in Tallinn, Estonia, in July 2020.

LabelPrint OÜ became a Durst Tau 330 customer already 5 years ago. Since then, they actively developed digital print services to its client base and a trustful relation has been built between Durst and LabelPrint OÜ during the past years. Therefore it was a logical step that Durst approached LabelPrint OÜ as the first-choice beta test candidate. After initial trials in late 2019, Sten Sarap, owner of LabelPrint OÜ, committed to be the beta test site for the new and revolutionary RSCi press. This was postponed for three months due to the COVID-19 lockdown.

The new Tau RSCi features print widths of 330, 420 or 508mm (13, 16.5 or 20 ins) and a higher printing speed of up to 100 linear m/min. New features for the RSC portfolio include a high opacity white print mode for an increased screen-like opacity and a high speed white mode that allows high speed printing at 80 lin. m/min of all colours, including white.

"This new press will mainly be used to transfer longer run flexo jobs onto a digital platform," said Mr. Sarap. "It is too early to make big statements. However, we are very confident that this new press with its revolutionary print quality and high printing speed will help us to reduce production cost and improve lead times. And thanks to its amazing print quality it will help to innovate our business and make us more competitive."

He added: "As a company that provides high quality sticker and print labels, the new Tau RSCi label press will be crucial in our mission to offer the shortest possible deadlines and competitive prices to meet customers' individual requirements and needs."

LabelPrint OÜs customer base includes beverage manufacturers, chemical and pharmaceutical industries as well as sectors. Formed almost 20 years ago, the company also has a sales office and warehouse at Tartu in the south of Estonia.

Helmuth Munter, Durst's Segment Manager, Labels and Flexible Packaging, said: "We're delighted to announce LabelPrint OÜ as the beta test site and wish them ongoing success. Labels continues to be a significant growth business for Durst, not least because increasing numbers of converters are recognising the benefits of transferring more volume from flexo to our digital platform. The introduction of the Tau RSCi has generated a large amount of interest in the marketplace since it was launched in September."

Proven existing packaging solutions can reduce environmental impact by up to 80% compared with traditional all-plastic packaging. Composites such as Inverform, by Iggesund Paperboard combine the re...

July 06 2020

Proven existing packaging solutions can reduce environmental impact by up to 80% compared with traditional all-plastic packaging. Composites such as Inverform, by Iggesund Paperboard combine the required strength, stiffness, and renewability qualities of paperboard with a thin plastic layer to satisfy hygiene requirements.

The hunt for materials that can replace plastic is intense. Innovation work is being done on a global scale to find renewable alternatives to plastic so that humanity can reduce the huge impact on the environment from our use of plastic. Many solutions are being tried but we still have no material with all of plastic’s great advantages without its devastating disadvantages. Instead of waiting for that magic material, which may never come, packaging buyers concerned about the climate should consider the existing alternatives and move to composite materials.

Proven packaging solutions already exist that combine a renewable material such as paperboard with a small amount of plastic, reducing their climate impact by over 80 per cent compared with traditional all-plastic packaging.

One very common type of food packaging is the plastic tray, which is then sealed for its onward journey to the consumer. Instead of making the entire tray of plastic, an easy alternative is to replace the plastic with a composite material consisting of renewable paperboard with a thin plastic layer that supplies the barrier properties needed to protect against moisture, grease and aromas. The stiffness and strength required for the construction comes from the paperboard’s wood fibres, and the plastic’s barrier properties provide the functional finishing touch. This relatively easy change of materials reduces the packaging’s climate impact by over 80 per cent.

“Plastic is an excellent material for packaging. It is very formable and provides the seal we need in food packaging with high hygiene requirements,” explains Stefan Söderberg, Sales Manager New Products at Iggesund Paperboard. He is leading the market launch of Inverform, a composite material from Iggesund that can replace all-plastic trays and greatly reduce the trays’ climate impact.

Various types of packaging made of plastic-coated paperboard have existed for decades. But thanks to the latest advances in paperboard manufacture, they have gained better functionality and reduced their climate impact. The debate over fossil versus renewable materials and their respective climate impacts has further placed the combination of plastic and paperboard in an increasingly positive light.

“The disadvantages of plastic packagings is that they are normally totally fossil based and are also not very easy to recycle,” comments Johan Granås, Sustainability Director at Iggesund Paperboard. “In comparison, our paperboard’s climate impact is about 90 per cent less than that of plastic. By combining paperboard with a thin plastic barrier, a packaging’s total climate impact can be radically reduced compared with that of plastic packaging.”

At least three serious problems are linked to humanity’s extensive use of plastic materials:

Miyakoshi Printing Machinery has launched a new inkjet press for flexible packaging, the MJP30AXF. The press uses water-based ink, claimed safe for food packaging. It comes in a 30in (...

June 22 2020

Miyakoshi Printing Machinery has launched a new inkjet press for flexible packaging, the MJP30AXF.

The press uses water-based ink, claimed safe for food packaging. It comes in a 30in (750mm) print width and runs at 50m/min with a print resolution of 1,200 x 1,200 DPI. The 5-colour press features CMYK+WW, and can handle materials between 12-100 micron. The press features integrated unwinder, corona treatment, pre-coater and rewinder.

Optimised production features include the ability to batch print a variety of jobs on the same web and printing of barcodes to manage post-press equipment. Automatic registration control and missing nozzle compensation minimise printing errors.

‘Currently the printing of flexible packaging is dominated by traditional analog printing technologies such as gravure and flexography, which enable very high productivity at low cost for long run printing jobs,’ said the company in a statement.

‘The challenge for these analog solutions today is that marketing focus has shifted from mass production to a more personalised approach. This requires brands to create an ever increasing variety of products produced in smaller quantities. This trend has led to a constant reduction in the size of production lots for which analogue devices are not well suited.’

Bobst unveils a new range of machines and solutions revolved around its vision for the packaging industry. At the heart of this vision is BOBST Connect, an open architecture cloud-based platform de...

June 15 2020

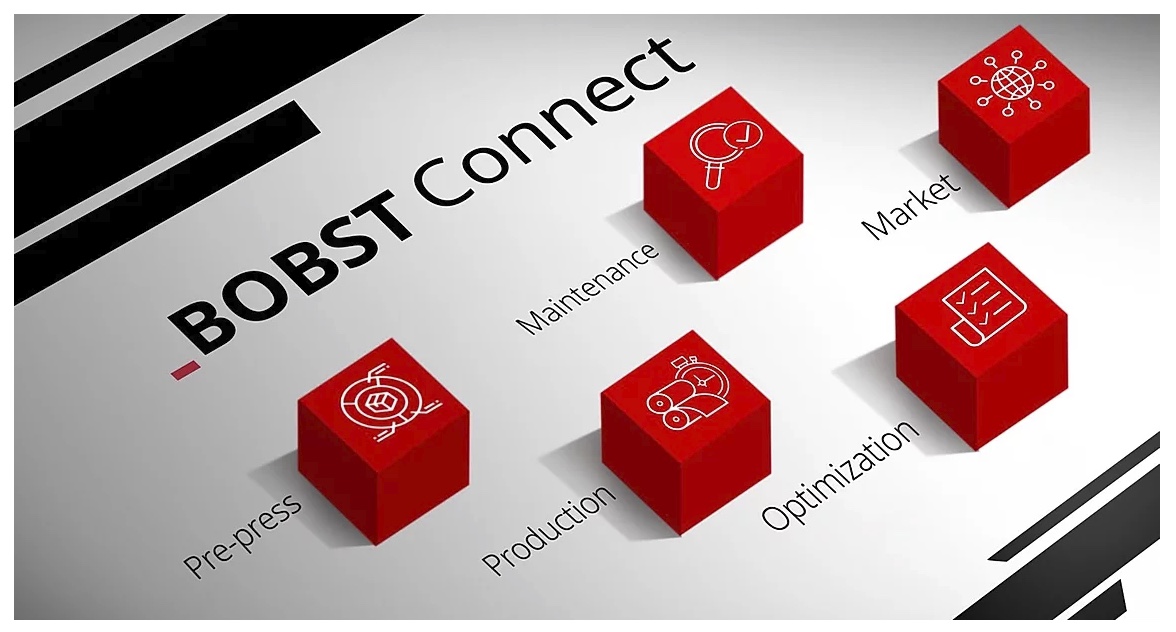

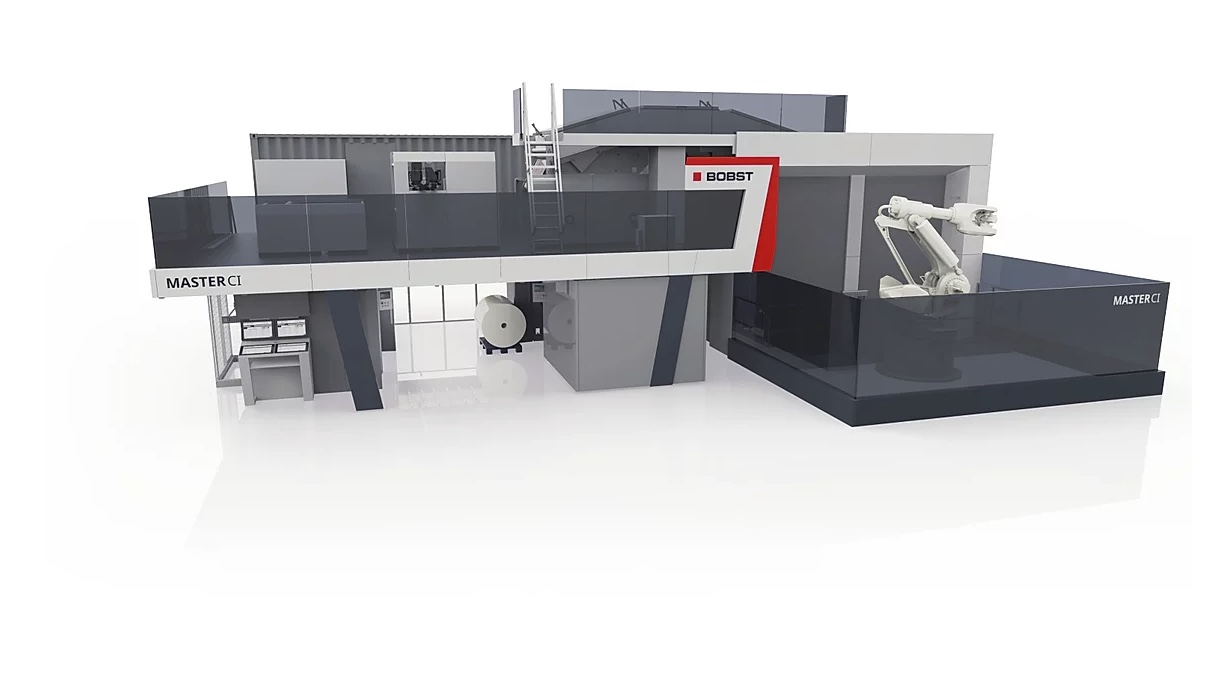

Bobst unveils a new range of machines and solutions revolved around its vision for the packaging industry. At the heart of this vision is BOBST Connect, an open architecture cloud-based platform delivering solutions for pre-press, production, process optimisation, maintenance and market access. It ensures an efficient dataflow between digital and physical worlds. It will orchestrate the entire production process from the client’s PDF to the finished product.

“The digitalisation of printing processes is the most visible element of progress in the packaging industry,” commented Jean-Pascal Bobst, CEO Bobst Group. “The coming years will likely see a major acceleration of digital printing and converting. While the solutions are becoming available, the biggest challenge for printers and converters is not the individual printing machines, but rather the entire workflow, encompassing converting.”

The reveal included the very latest generation of laminators, flexo presses, die-cutters, folder-gluers and other innovations, reflecting the company’s drive to transform the industry.

The newly announced equipment included:

For the folding carton industry

Esko, a global developer of integrated hardware and software solutions for the print, packaging and label industries, and AVT Inspection Systems Inc. (‘AVT’), global provider of print i...

June 08 2020

Esko, a global developer of integrated hardware and software solutions for the print, packaging and label industries, and AVT Inspection Systems Inc. (‘AVT’), global provider of print inspection, process control and quality assurance solutions, are pleased to announce the integration of their businesses.

Effective immediately, the integration is designed to deliver simplicity and extended connectivity for both Esko and AVT customers by incorporating automated quality inspection into the connected packaging and labelling value chains.

Esko + AVT Sharing many of the same customers around the world, the combined business will see expansion of its sales and technical service teams with enhanced local representation, ensuring customers and OEM partners receive the same level of customer service and technical excellence they have come to expect from both companies.

Mattias Byström, President, Packaging & Colour Businesses at Danaher (Pantone, Esko & X-Rite), commented, “We are on a mission to build trust in packaging for the long term. This means we are focused on continuously improving the specification, measurement and communication between parties across the global packaging value chain. By removing the organisational barriers between AVT and Esko, we are expediting this vision.”

The aim of the new organisation is for customers to communicate and measure print quality and colour, from end to end on a global basis, delivering easier, faster, and more accurate right first time production to boost operational performance and ultimately customer satisfaction.

Roy Porat, President of AVT, added: “Above all, this integration will absolutely deliver simplicity. It will be easier for printers to measure print quality and colour, easier for operators to hit quality and colour targets, easier for teams to track and share quality and colour data, and easier for business leaders to buy and implement these solutions. Bringing our combined strengths together to deliver a complete solution is an exciting opportunity for our customers and our business.”

Esko and AVT have already released AutoSet, a digital link between Automation Engine, the Esko packaging prepress workflow server, and the AVT 100% print inspection solutions. Enabling Automation Engine to setup AVT inspection systems on conventional and digital presses, as well as on rewinders in an automated way, the development forged the path for the two businesses to work more closely together.

AVT was acquired by Danaher, the Esko parent company, in 2017 to support its vision of digitising the packaging value chain. Mattias Byström expanded his leadership role from Esko President to include oversight of AVT in August 2019. This latest strategic move is the formalisation of the strategy to create a combined position to better serve brands and their print and packaging supply chain partners with comprehensive hardware and software solutions.

To find out more, please visit www.esko.com

All LittleRed X-Series conveyor dryers and DTG-capable XD-Series conveyor dryers now feature an upgraded exhaust system that increases drying efficiency, reduces noise levels and improves operator ...

June 01 2020

All LittleRed X-Series conveyor dryers and DTG-capable XD-Series conveyor dryers now feature an upgraded exhaust system that increases drying efficiency, reduces noise levels and improves operator safety, it was announced by Vastex president Mark Vasilantone.

“The new air mapping system is more powerful, removing fumes and moisture through an enlarged stack, preventing contamination of the shop environment,” explains Mr. Vasilantone. “The air flow also cools the skin of the heating chamber and control panel, improving operator safety and comfort.”

The upgrade is standard on LittleRed-X1, -X2 and -X3 models for curing of screen-printed plastisols, water-based inks and discharge, and on LittleRed-X1D, -X2D and -X3D models additionally capable of curing DTG-printed digital white ink.

Increasing the powered exhaust diameter by 5 cm for each model improves drying capacity by approximately 10 percent in high-moisture applications like water-based inks and DTG printing, according to Mr. Vasilantone.

Exhaust ducting now exits the dryers vertically from the top of the chamber instead of from the side, eliminating the additional width and 90-degree elbow previously required, while reducing noise significantly.

All LittleRed dryers are offered in multiple belt widths, as narrow as 46 cm for the narrowest LittleRed-X1D model, and up to 198 cm for the widest LittleRed-X3D model.

Capacities range from 90 to 1080 plastisol-printed garments/h, 45 to 555 water-based or discharge-printed garments/h, and 34 to 155 DTG garments/h printed with digital white ink or pretreated for DTG printing.

Modular heating chambers can be added and conveyor belts lengthened to double or triple conveyor belt speeds and drying capacities as needs grow.

The heaters of all Vastex dryers carry an industry-leading 15-year warranty, and feature closely spaced coils to provide high-density, medium-wavelength infrared heat for maximum cure speed without cold spots or under curing associated with conventional units.